Part and sprue sticking stem from multifaceted issues, with mold-related failures being primary culprits. Key reasons and remedies are outlined below.

Problem: Gouges, nicks, or dents in the cavity or sprue bush create friction, trapping parts/sprue and hindering ejection.

Solution: Polish surfaces to enhance finish; chrome-plate cavity interiors. Ensure polishing aligns with melt flow direction to minimize resistance.

Problem: Worn molds or oversized insert gaps allow flash formation, jamming parts during ejection.

Solution: Repair damaged areas and reduce insert clearances to prevent flash intrusion.

Problem: Low rigidity causes mold deformation under injection pressure. Post-cooling, rebound force clamps parts, blocking mold opening—even if deformation is elastic.

Solution:

Design molds with sufficient strength; use dial indicators during trials to monitor deformation.

Start with low injection pressure, gradually increasing while controlling deformation.

For stuck molds, disassemble, heat-soften parts, and add external frames to reinforce rigidity.

Problem: Inadequate draft angles (≤3°) or misaligned core-cavity plates cause part sticking, leading to warping, ejection marks, or cracks.

Solution: Ensure minimum draft angles (≥5° for complex parts); maintain core-cavity parallelism to prevent cavity misalignment.

Problem: Long/small runners, weak main-branch connections, missing cold slug wells, or mismatched nozzle-gate dimensions cause sticking.

Solution:

Shorten runners, increase cross-sections, and add cold slug wells.

Balance multi-cavity filling with auxiliary gates; size main runner diameter 0.5–1mm larger than the nozzle, and gate sleeve radius 1–2mm larger than the nozzle.

Problem: Insufficient ejection stroke, uneven force distribution, or sticky ejector plates trap parts.

Solution:

Maximize ejection area and stroke; maintain moderate ejection speed (10–30 mm/s).

Lubricate sliders to eliminate sticking and ensure smooth ejector plate movement.

Surface Treatment: Polish and chrome-plate mold surfaces.

Rigidity Control: Strengthen molds and monitor deformation during trials.

Design Optimization: Adjust draft angles, gate dimensions, and ejection systems.

Process Tuning: Gradually increase injection pressure and ensure proper cooling before ejection.

Sticking defects require integrated solutions across mold design, material selection, and process control to ensure smooth ejection and part quality.

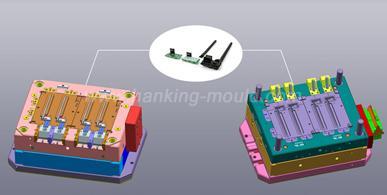

We specialize in plastic injection mold manufacturing service and injection molding processes for 20 years, contact yoyo@hanking-mould.com for your plastic products projects.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China