automotive molds manufacturers are plentiful in the current market, and when choosing a specific one, you can also look at which companies have a certain level of reputation in the market, and can produce moulds with guaranteed quality.

In fact, moulds are selling very well in the market now, and there are many types of models that can be processed and made. When we have a specific understanding, we can also look at how to choose professional automotive molds processing factory, and mastering certain methods can ensure that the selection process is easier.

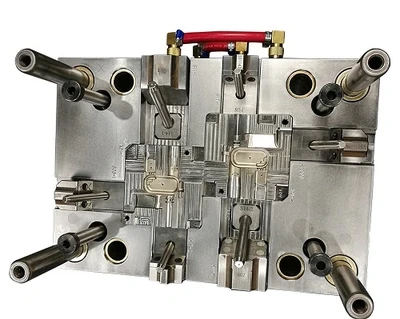

Professional companies also need to use certain equipment when making moulds, because in the era of high-tech development, automation equipment is needed to effectively provide production efficiency. And many automotive molds themselves cannot be operated properly and can only be made with plastic moulds.

When choosing the automotive molds manufacturer, you can choose based on the manufacturer's production equipment to confirm the quality of the produced moulds.

Mould manufacturing companies with strong reputation and strength have a certain level of fame in the market, and the types of moulds produced vary widely. For example, we often see many food industry products require some moulds for processing and making small bottle caps. Choosing a professional manufacturing company can indeed ensure that automotive molds are made better, and of course, it can also ensure the quality of the products in the later stage. It seems that the selection process is also very easy.

Some mould manufacturing companies have very strong strength in the actual operation process. You can also see that in addition to having a certain level of brand reputation, choosing a professional company is also because the company's business strength is very strong. The role of moulds is very obvious in the actual use process, and they can really be used to produce many products.

HANKING MOULD designs and manufactures plastic injection moulds in China, providing our global customers with large factories and injection production services, including secondary processing and assembly. Our global customers come from the United States, Germany, Switzerland, France, Italy, Austria, Israel, etc. Please feel free to contact us.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China