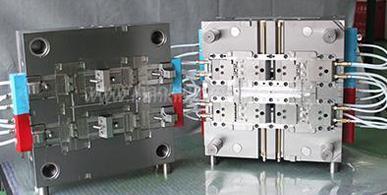

1. At the beginning of the design of each injection product mold, the mold opening direction and parting line must be determined first to ensure that the core-pulling slider mechanism is minimized and the effect of the parting line on the appearance is eliminated.

2. Analyze every detail in the design of each mold.

3. Appropriate draft angle can avoid drag mark, scratch etc.

4. When designing, refer to previous similar designs, and understand the situation in its mold processing and product production, and learn from the experience and lessons.

5. When designing injection products, the contradiction between product appearance, performance and process must be considered comprehensively. Sometimes a part of the manufacturability can be sacrificed to get a good appearance or performance.

6. Learn more about the characteristics of the injection molding machine, and design the mold according to the injection molding machine used for the products.

7. Design the clip structure to multiple clips at the same time, so that the overall device will not be inoperable due to the damage of individual clips, thereby increasing its service life, and more filtering and rounding corners to increase strength.

8. Choose the processing method according to the product structure, because each processing has its limitations, try to choose an easy-to-do method. Help customers find alternative ways to reduce processing pressure for difficult structure.

9. The product identification is generally set on the inner surface of the product on a relatively flat surface, and adopts a convex form. Choose the surface where the normal direction and the mold opening direction ruler may be consistent to set the logo to avoid drag mark.

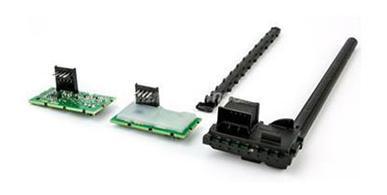

10. Inserting in injection molded products can increase local strength, hardness, dimensional accuracy and set small threaded holes (shafts) to meet various special needs. At the same time, it will increase product costs.

11. Try to use the previously successful mold structure when design a new mold.

13. Setting a reasonable fillet can also improve the processing technology of the mold.

14. Analyze the impact of different gates on the plastic products.

15. As far as possible, the pillar should not be used alone. It should be connected to the outer wall or used with ribs. The purpose is to strengthen the pillar and make the plastic flow more smoothly.

16. Don't stop learning, learn from experienced senior injection mold designers.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China