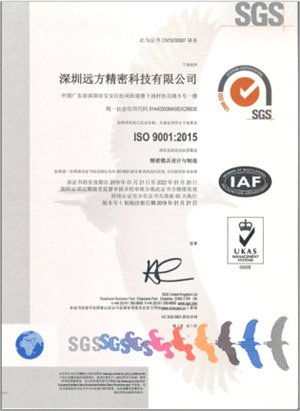

Customer Oriented & Continuous Improvement

Main QC Procedure

Customer's Mold Specification Sheet Check

Design Optimize Control

Steel Hardness Inspection

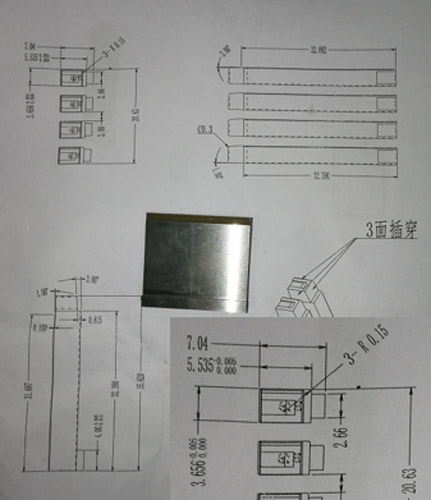

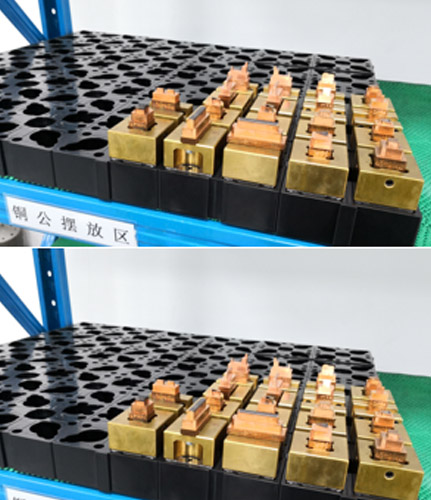

Electrodes Inspection

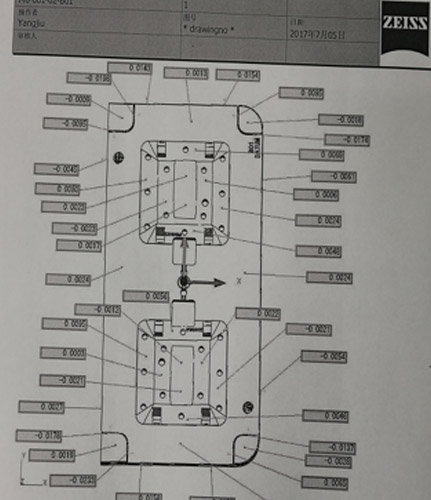

Core and Cavity Steel Dimension Inspection

Pre-Assembly Inspection

Trial Report and Samples Inspection

Final Full Inspection (prior shipping)

Mould Package Inspection

English

English Deutsch

Deutsch italiano

italiano русский

русский français

français română

română العربية

العربية Español

Español Polska

Polska 日本語

日本語 한국어

한국어

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.