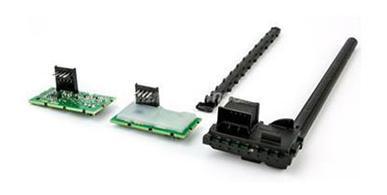

The over-molding part is a process that can bond different materials by the injection molding.

Over-molding in HanKing is a technology to combine two different moulds while we called the combination of different resins in one mould as two-shot. Knowledge of plastic resin compatibility is very crucial for over-molding, HanKing's expertise assure the performance of the over-molding part is bonded strong.

There are many factors in the selection of over-molding resins, it depends on the properties of the basic resin and on the other hand on the application properties. Specifically, there are the following:

Corrosion resistance.

Flame retardant (in line with ecological and environmental requirements). The eco-friendly logo is a sign that the product meets environmental and social standards.

Wear resistance (to avoid sink or stripping).

Shore hardness (in accordance with soft feeling or other requirements).

Impact resistance (in accordance with structural requirements).

Melting point (Meets application temperature requirements and does not soften or deform).

Bonding method (mechanical interlocking is formed when the two materials do not match, and chemical bonding is formed when the two materials match).

In general, the matching material should have similar chemical properties or contain matching composite elements. When the basic resin does not match the covering material, it usually only forms a mechanical interlocking effect, not a chemical bonding.

Soft plastic resin can be molded with different materials, but it is more limiter and stricter when hard plastic is over-molded with other hard resin.

It is acceptable to over-molded a plastic part with two hard resins in small areas, but it cannot be used in large areas and designed the second hard plastic over-molded the first hard resin as a closed ring.

From design work as mould base selection, wall thickness, filling balance, ejector balance, even venting to subsequent manufacturing process, HanKing will consider all the details in order to make a mold that will satisfy the customer.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.