Plastic Tooling Technology HanKing Mould Can Offer:

Multi-Cavity

2K Molds

Over-molding

Babyplas

Stack mold

Unscrewing mold

Silicon mold

Metal injection mold(MIM)

Gas-Assisted molding

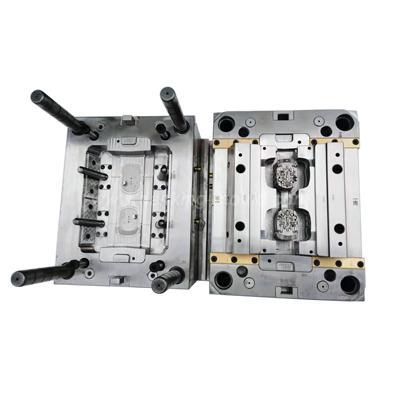

With a full air-condition plastic injection mold fabrication workshop possessing different plastic mold fabrication machines and expertise, we can offer plastic tooling manufacturing services from small precise parts to middle-big complex automotive parts.

Multi-Cavity

2K Molds

Over-molding

Babyplas

Stack mold

Unscrewing mold

Silicon mold

Metal injection mold(MIM)

Gas-Assisted molding

Our skillful plastic molding manufacturing workforce combines with the strict process and quality control capability to secure our plastic molds at high-quality level, we provide not only plastics moulds but also technical support, speed, efficiency & quality.

The key point of high-quality injection molds & molding is:

Great plastic mold design;

high-precision plastic molding machining equipment;

seasoned bench workers and a good management team.

In HanKing Mould Shenzhen Songgang plastic mold manufacturing factory, we have them all. Our 45+ tooling engineers are very experienced in Europe Tooling Standard and American. Below are some plastic molding parts and injection mold example we have. made.

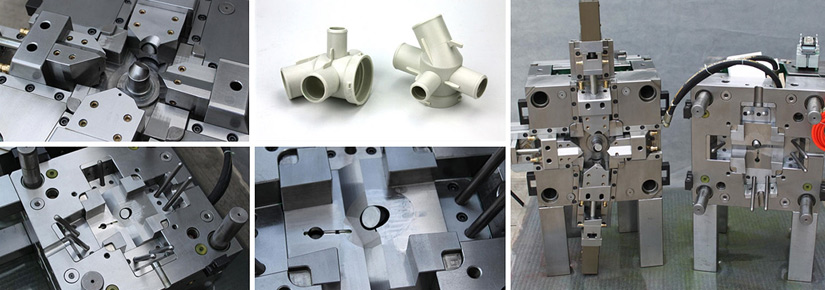

The product above the picture is a five way water pipe joint which is used for household appliances mould, the part structure is complex, and high precision tolerance since need connect with other pipes.

1. four cylinders to control the sliders

There are many undercuts in this plastic joints, and we can see the holes are in different directions, the holes need to be molded by sliders, four core pulling sliders, and cavity side oblique slider, these sliders need to be opened in sequence, so HanKing Mould designers used four cylinders to control the sliders.

2. adopted secondary sliders

Meanwhile the plastic water pipe joint part has feature of thick wall and deep ribs, there is a very large risk of deformation and drag mark, Hanking Mould designers adopted secondary sliders, that is, for the same slider, release a part of slider first, and the release other sliders.

3. adopted the optimal cooling design for each slider

So many sliders are used, it extends the production cycle time which means that the time required to complete a production is increased. In order to solve this problem, improve the production efficiency and reduce the single production cost, HanKing Mould adopted the optimal cooling design for each slider to shorten the cycle time.

The life cycle of this injection molds reaches 1 million, after the mold was delivered to the European customers, the production process was very smooth and the customers were particularly satisfied. Until now, the customers still cooperate with HanKing Mould, because our quality and design capability have won the customers' trust and choice.

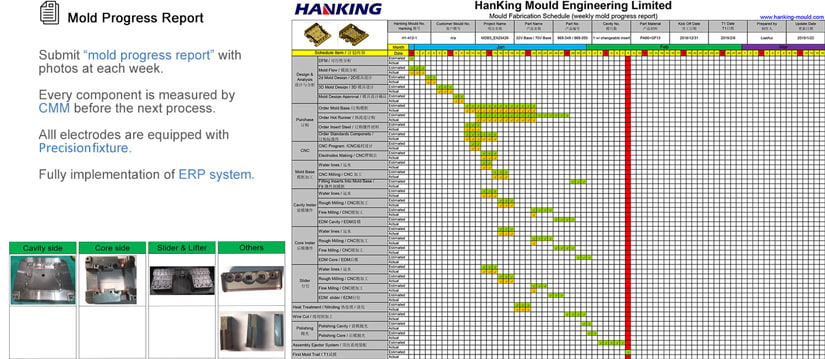

HanKing Mould plastic mold manufacturing progress report

Submit Mold Progress Report with photos at each week;

Every component is measured by CMM before the next process;

All electrodes are equipped with Precision Fixture;

Fully implementation of ERP System

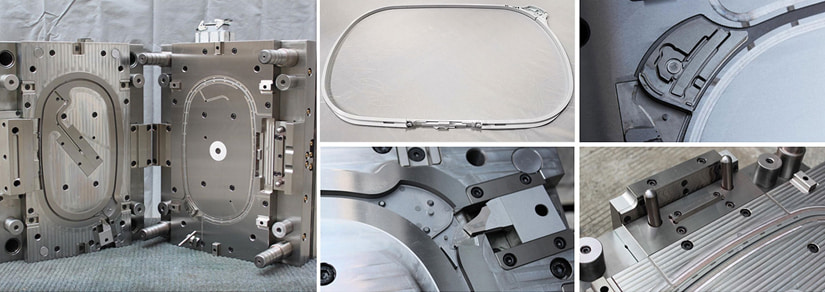

The product above the picture is a very famous plastic frame for the panel of household sewing machine. Because of our outstanding mold quality, customers choose us to make their plastic injection molds for each new product. The material of this plastic frame is Nylon with high glass fiber content up to 50%. This plastic frame has some appearance surface, and the other part is the assembly surface. There are many holes in the part connected with the main equipment that can be fixed with the hook.

Due to many defects of glass fiber reinforced nylon, it is easy to cause poor surface appearance, including burning, glass fiber exposure, flash, surface blooming, silk mark, spark, etc. The customer requires that the products produced should have a good appearance without affecting the assembly function.

1. reasonable gate position and shape

We need to avoid these defects for customers when designing molds, the reasonable gate position and shape are the first job for designers. The gate must not be set on the product surface, we must also avoid the area of the fitting holes, these holes were molded from sliders and inserts.

2. carefully plan size and number of ejector pin

This plastic frame is not small size, large products need to be ejected with big power, designers need to carefully plan size and number of ejector pin, and all ejector pins must avoid cooling channels. Enough strength is required to eject the product without interfering with the cooling pipe or damaging the appearance. As a result, HanKing Mould made a perfect quality injection mould.

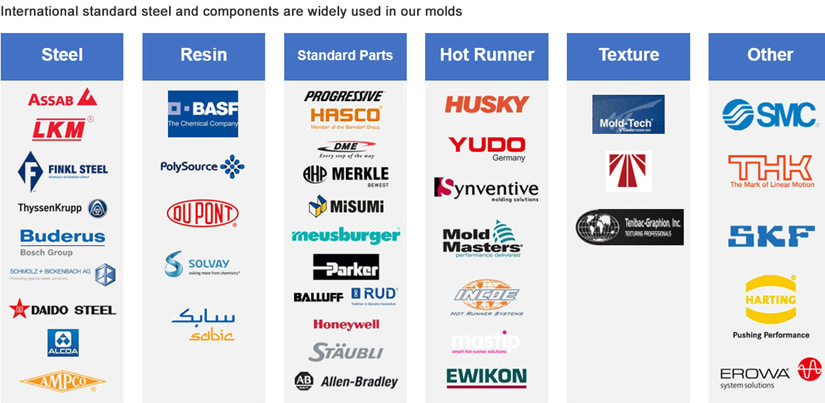

international standard steel and components are widely used in HanKing Mould's plastic mold manufacturing process

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.