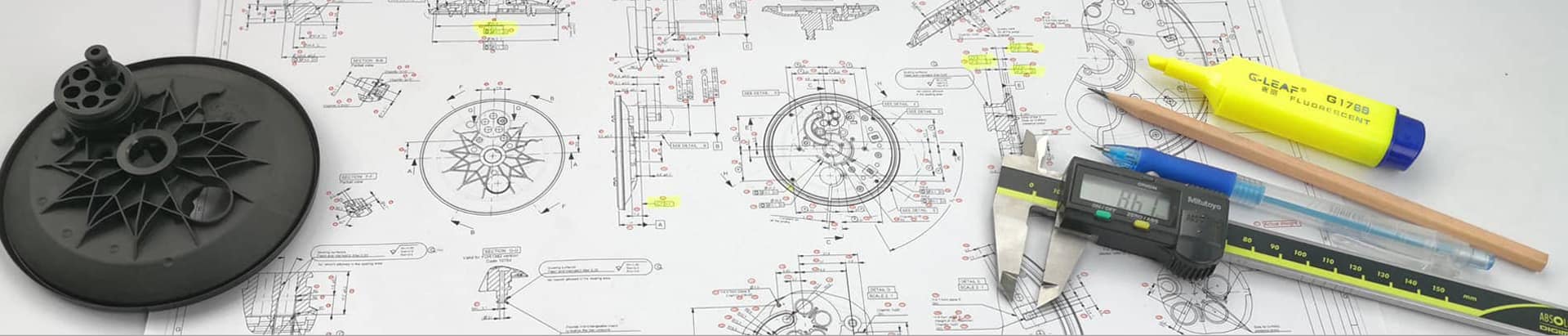

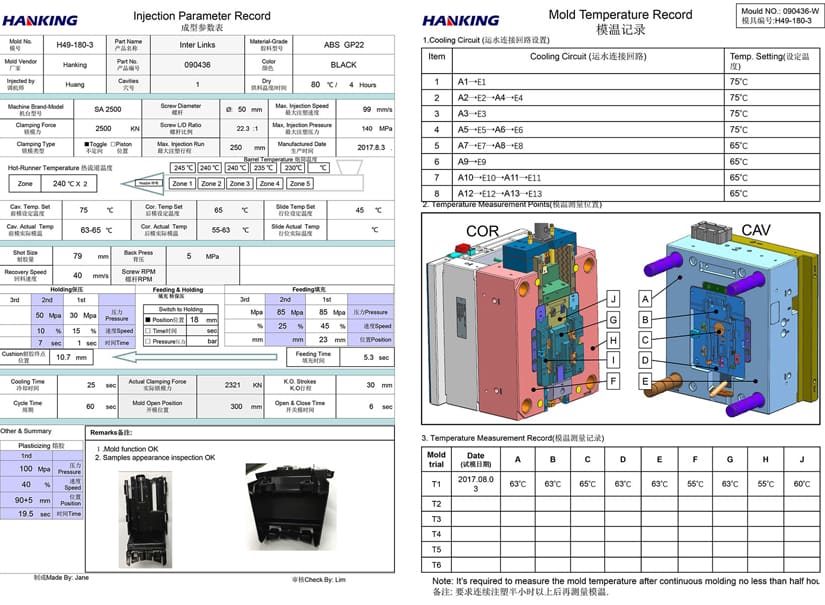

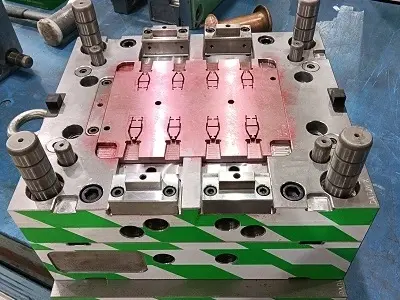

Mold Trials Simulating Manufacturing Conditions Are Performed on Every Mold

Using the latest molding trial process and plastic injection molding machines, HanKing is capable to analyze every step of the plastic injection molding process to assist in debugging and qualifying the moulds.

English

English Deutsch

Deutsch italiano

italiano русский

русский français

français română

română العربية

العربية Español

Español Polska

Polska 日本語

日本語 한국어

한국어

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.