HanKing Mould uses the most popular mold design and mould engineering software such as roE, SolidWorks, AutoCAD/Autodesk, Unigraphics, and so on.. At HanKing we work with customers no matter they have complete specifications or just a preliminary development plans. Our plastic mould engineering team will assist you in developing a clear understanding of your requirements and help you make the important decisions that will speed your design to mass production.

The way to lower plastic mould costs and improve higher efficiency begins at the design level.

If want to maintain the quality of the mold, we can't reduce cost by change the mold materials and processing costs. If low-cost materials or cost saving processing methods are used, the mold maintenance rate will increase, on the contrary, it will increase the production cost.

High quality molds are those that can achieve high efficiency, high quality, low loss, few mold failures and successfully complete the production of injection molding products. Good injection mold can maximize the output, reduce the rate of maintenance, and stabilize the injection molding production, so as to reduce the cost of the production process and reduce the single production cost of plastic products.

Mature mold design scheme is the most important prerequisite for injection mold quality. Before the injection mold design, the mold processing and subsequent injection molding are analyzed to reduce costs and improve efficiency.

The ejection mechanism of the injection mold should be strong enough to avoid problems such as unbalanced ejection, product protrusion, and product ejection deformation caused by saving ejector pins. The losses caused by subsequent mold modification and mold testing are far greater than those caused by several ejector pins cost.

HanKing Mould a professional precision mold manufacturer, our mold designers have accumulated a lot of experience in designing various types of molds for customers all year round. They know how to design excellent quality injection molds and solve design problems for customers.

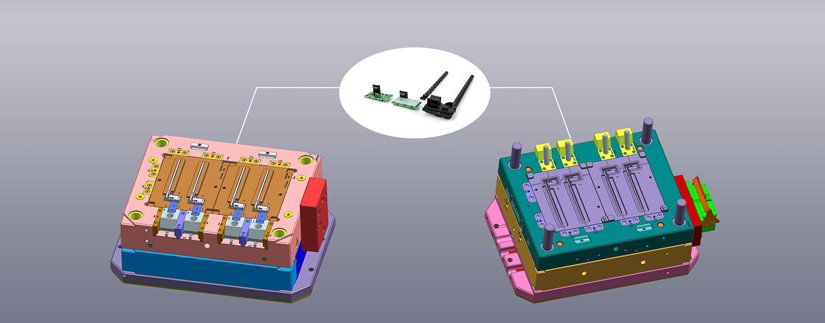

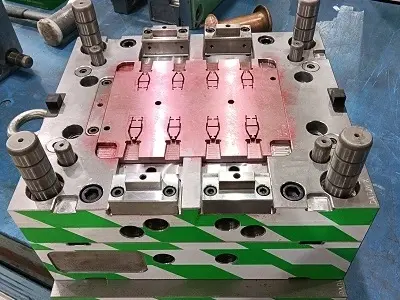

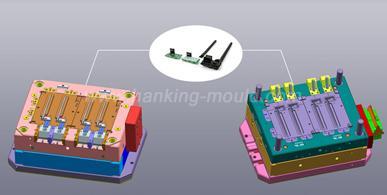

As shown in the picture, the process of the products is very complex. This plastic product connects with circuit boards, antennas, and hardware inserts. According to the traditional practice, they need to be made one by one, with a long time, high cost, and high defect rate. Our design engineers optimize the mold design, multiple processes can be combined to form a set of one-time injection molding processes, which can not only effectively protect the circuit board and reduce the defective rate, but also greatly improve the processing effect and reduce the production cost.

This is the importance of the preliminary design work. Good design engineers will solve problems for customers, in HanKing Mould, we have many excellent design engineers serve you.

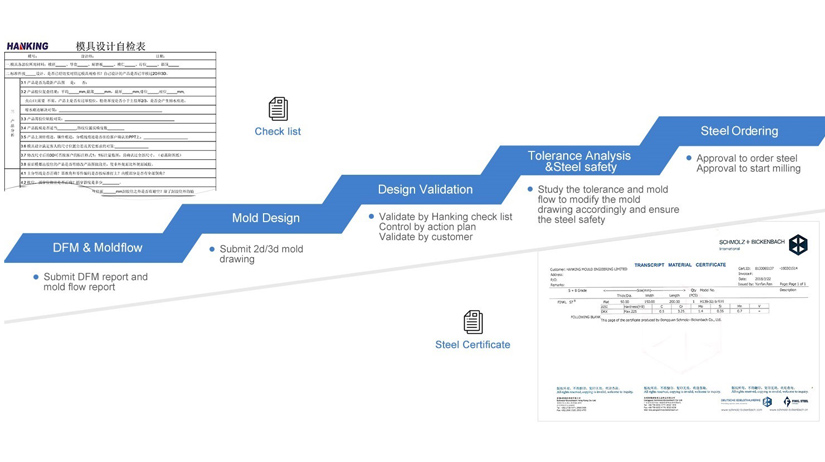

custom molding design and engineering procedure

DFM & Moldflow: submit DFM report and mold flow report

Plastic Mold Design: submit 2d/3d mold drawing

Design Validation: validate by HanKing Mould checklist; Control by action plan; Validate by customers

Tolerance Analysis & Steel Safety: Study the tolerance and mold flow to modify the plastic mold drawing accordingly and ensure the steel safety

Steel Ordering: Approval to order steel; Approval to start milling

Ask HanKing Mould for a custom mold engineering and design checklist and steel certificate

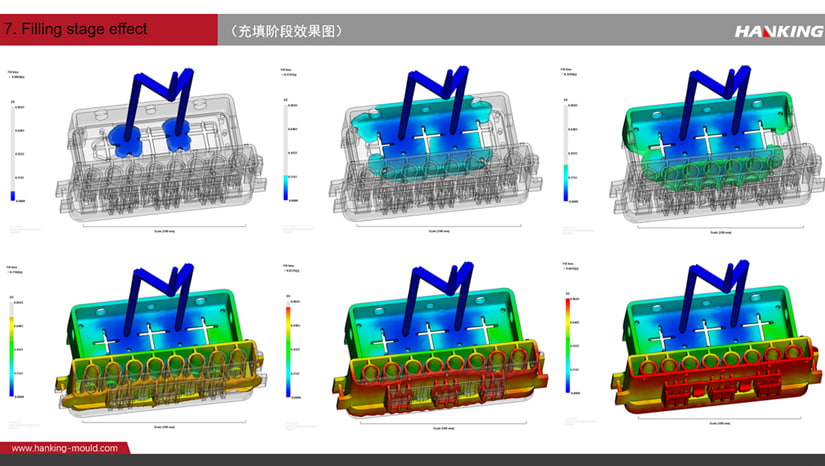

filling stage effect

Filling is the first step of injection molding, and the filling is completed when the molten plastic enters the mold cavity to close.

Filling analysis is very important, which is the key factor to obtain good finished plastic products. Because the plastic parts are usually irregular in shape, instead of a flat plate, and different plastics have different melting states.

In the injection molding process, the material is subjected to high shear force at the injection stage. The shear rate is proportional to the filling speed. If the shear rate is low and the filling speed is set at the initial non Newtonian region of the viscosity curve, a small change in the shear rate will cause a large fluctuation in the plastic viscosity. In the long run, such fluctuations will lead to inconsistent filling rates, which will lead to changes in the quality of injection molded products.

Therefore, it is necessary to analyze the problems that will occur in the filling process of injection molding according to the characteristics of plastic materials and the abnormalities of product structure, and resolve these problems during mold design.

The first stage of injection filling is where the material is fed from the product. HanKing Mould will analyze where the material is fed, and analyze if different gates can be completely filled, whether the air is trapped, and whether the shrinkage is serious. If the filling analysis proves that there are problems, the designer can solve these problems to avoid unnecessary mold modification. The picture shows the path of plastic material filling., in the picture, the red color indicates that need longer filling time.

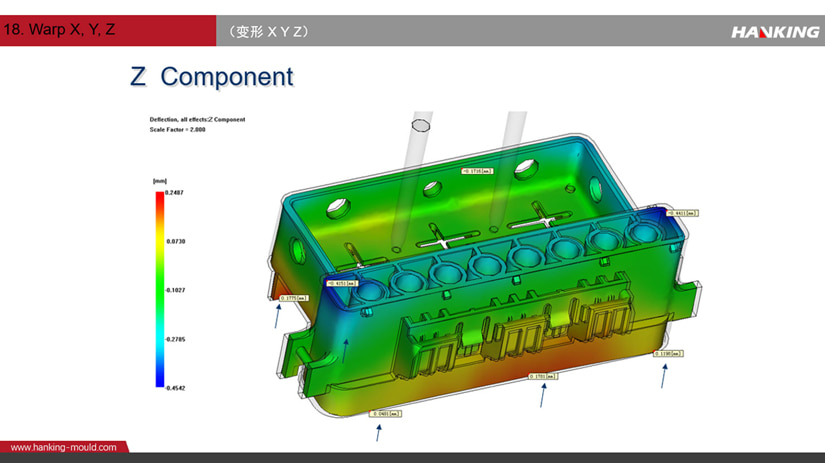

Wrap X, Y, Z component

HanKing Mould engineers always do their best to consider every point in plastic mould design stage to avoid losing for future modification in plastic production.

During the injection molding process, the shape or volume of the plastic part changes.

Deformation is one of the common defects of plastic parts, deformation will lead to uneven assembly clearance of products, it may have step between the assembly components, which will seriously affect the appearance and assembly effect of products.

In general, the causes of plastic product deformation are as follows

The product structure design, the wall thickness is uneven, also the product shape and structure are unstable, which will cause deformation of injection molded products

The design structure of the mold, the position of the gate point, the shape of the gate, and the ejection system.

Injection molding conditions, such as injection pressure, speed, time, and mold stability.

Reasons for deformation of plastic products include but are not limited to temperature, pressure and speed.

The pressure inside the mold is very large. The pressure will cause internal stress in the plastic parts. And the temperature distribution of different part of the product is different, during the cooling process of the plastic parts, the residual internal stress will be released, and causing deformation, uneven shrinkage and uneven cooling are also factors that cause deformation of plastic parts.

It is difficult to solve the problem of warping deformation through process parameters, therefore, in the design stage, highly experienced design engineers are required to analyze the deformation of products, discuss whether the products are warped and the causes of deformation, and propose corresponding improvement countermeasures.

Generally speaking, the designer needs to exclude the possible influence of the gating system on the deformation. The cooling speed is also a design concern, and at the same time, the deformation in the demoulding process should also be avoided.

In case of deformation, the designer should start from the mold design direction, increase the runner, change the gate feeding position, change the gate form, or even change the parting line, increase ribs, or reduce the step difference, and try not to change the customer's product structure.

The product in the above picture is our deformation analysis. The maximum deformation in Z direction is only 0.2. This effect is good, indicating that the product has no serious deformation problem.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China