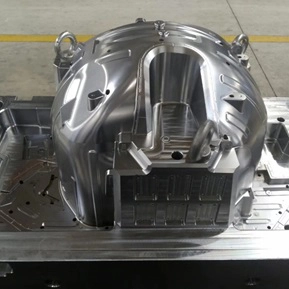

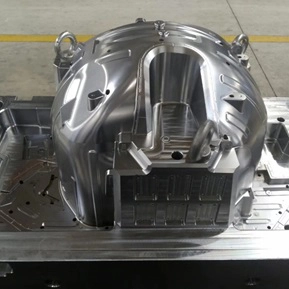

Auto Parts Mold

We are plastic injection mold making factory not trading company.

Mold material: NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, etc.

Main processing equipment: drilling machine, CNC, slow wire cut,

grinding machine, spark machine (ordinary/mirror), milling machine,

mold assembly, injection molding machine.

Cooperation process: inquiry quotation contract research and development

mold injection molding after-sales service.

Applicable processing types: injection molding, polishing, spray painting,

silk screen printing, laser engraving.

Auto Parts Mold for High-Quality Plastic Injection Automobile Parts

Innovation, precision, and impeccable quality auto parts mold are the cornerstones of our business.

Partner with HanKing Mould and experience the difference in auto parts mold design and manufacturing. Contact us today

to discuss your specific requirements and discover how we can support your business's success.

With a broad customer base spanning Europe and the United States, HanKing Mould has established a reputation for

delivering exceptional precision mold parts. Our 3,000 square meter facility and talented workforce of more than 60

employees enable us to offer the utmost in manufacturing capabilities. We are dedicated to providing personalized service,

unparalleled attention to detail, and reliable delivery times to our valued customers.

HanKing Mould has been specializing in manufacturing auto parts mold for many years, mastering core production

technologies, and having 16 years of international trade experience; Complete production standards and processes;

Quickly achieve mass production with a precision of 0.01; High efficiency, high response speed, and quick problem-solving.

On the mold material, use high-quality mold steel. Professional and experienced engineering advanced processing

technology. Reasonable mold structure and high-quality detail control; Solve problems such as unstable production capacity,

short service life, easy generation of sharp edges (burrs), and mold deformation

How long does it take to work at each stage after the auto parts mold contract is signed?

1. After signing the contract, there will be 3-4 days to check with the customer first, and both parties will communicate some

specific requirements for the mold;

2. The mold design time is approximately 5-7 days, and material procurement will be carried out during the same period;

3. The production time of the mold is approximately 20-35 days, which varies depending on the size and complexity of the mold;

4. The trial mold and inspection time is approximately 2-3 days;

5. After the T1 mold trial, the mold repair time is about 3-5 days. Then make T2 mold trial, usually need three times mold trial

which can basically meet the requirements.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China