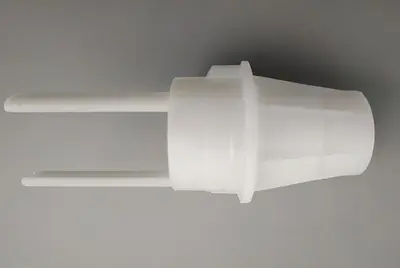

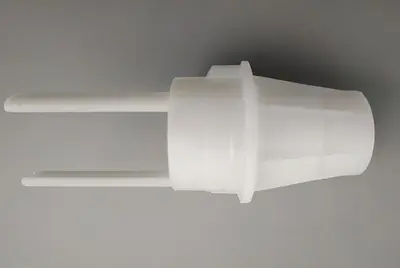

Insert molding refers to a molding process in which an integrated product is made by inserting a pre-prepared metal material insert into a mould and then injecting the plastic resin, and the molten material is bonded to the insert, cooled and solidified.

Insert molding features are as follows:

The moldability and flexibility of plastic resins, as well as the rigidity, strength and heat resistance of metal parts, create complex and sophisticated metal-plastic integrated products.

In particular, the electrical product made by insert molding, together with the insulation of the resin and the electrical conductivity of the metal, can meet the basic functions of electrical products.

The pre-formed combination of multiple inserts makes the subsequent product unit combination engineering more rational.

Inserts are not limited to metal, but also cloth, paper, wire, plastic, glass, wood, wire, electrical parts and so on.

For the rigid molded product and the curved elastic molded product on the rubber gasket plate, the parts by insert molding can eliminate the complicated operation of installing the sealing ring, and help the subsequent process automation.

Compare to the press-in molding, the metal insert gap can be designed to be narrower, and the reliability of the composite product molding is higher as the plastic resin is molten to wrapped with the metal insert.

Selecting the appropriate plastic resin and injection molding conditions, even for products that are easily deformed or broken (such as glass, coils, electrical parts, etc.), can be sealed and fixed by insert molding with plastic resin.

Designed the appropriate mould construction, the insert can also be completely enclosed in the plastic resin.

By the combination of a vertical injection molding machine and a robot, insert arranging mechanism, most of the insert molding projects can be automated.

The product with a hollow groove also can be made by insert molding after the core hold treatment.

Automatic insert molding system design points:

The shrinkage rate of metal insert molding is not uniform, and the limit test of the shape and dimensional accuracy of the important areas should be done in advance.

The metal insert has the possibility of deformation and displacement during the injection process, and the designer should be fully considered about mould construction to help stabilize the metal insert. For products whose insert shape cannot be changed, prior testing is indispensable.

Where the arrangement of the metal inserts is separated and the conveyor is used, the contact between the metal inserts and the plastic and the vibrating balls may cause slight damage to the surface of the insert, which may affect the quality of the product, the quality tolerance limit should be confirmed in advance.

The zigzag shape, the amount of warpage, the difference in material thickness, the difference in diameter, and the difference in thickness due to metal plating processing of the metal insert due to the press working should be determined in advance. Carried out the design of the automation device and the design of the mould structure on this basis.

Mould gate position, molding cycle time, etc., which are the key points of the mould structure, are solved as much as possible or have corresponding improvement solutions.

It should be confirmed whether the metal insert needs to be preheated or dried. The aim is to ensure the quality and stability of the molding.

The various testing devices installed in the mold are used to prevent the molding action from being affected by environmental conditions such as heat, force, vibration, etc., and it should be confirmed whether it is used or not.

Hanking Mould is a responsible insert molding manufacturer in China and has experience in manufacturing and supplying custom plastic injection molding service for many years. Our production sites have been accredited the certification of TS16949, ISO 14001 and ISO 9001, etc. We provide diverse insert molding solutions for you. You can fully trust our production sites, products and place your orders.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.