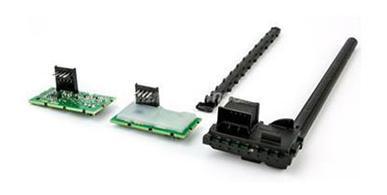

In HanKing Mould Shenzhen headquarter we can provide injection molding secondary processes, semi-finished & finished product assembly such as Spray painting, Pad print, Silkscreen, Ultrasonic Welding, Laser Etching, Sand Spraying.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China