Home appliance mould is also known as household appliance mould which is used to produce plastic parts and components for the household electric appliance.

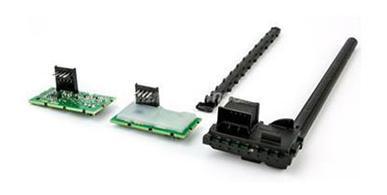

The household appliance moulds generally include interior plastic parts mold and the exterior plastic housing or case.

For interior parts, dimensional accuracy is the most important, and there is usually no special requirement for appearance, as long as it does not affect the assembly of the products.

For exterior plastic housing or cases, the appearance and size are both important, but the exception is that some housing or cases will go to secondary processing, such as painting, plating etc., so that the injection-moulded exterior housing usually is not required to be high polish, only in some specific areas that affect the subsequent process are high polished.

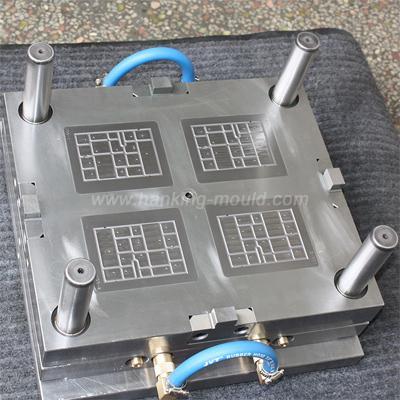

How to ensure the accuracy of the plastic parts? First of all, to ensure the accuracy of the mould steel dimension. In HanKing, all the dimensions in the molds are within tolerance measured by CMM Zaiss before the moulds are delivered to our customers. We have good designers with more than 15 years of experience, providing good solutions and professional technical support. When we are designing a house appliance plastic injection mold, we should choose the mould steel by combining the total life cycles and the plastic resin of the part. Make inserts as much as possible for important dimensions or special structure area and some fragile ribs, because the inserts can be replaced and convenient maintenance after a long period of production. And machining by grinder as much as possible, in terms of accuracy, the grinding machine has its' advantage.

Every kind of machine has different advantages, toolmakers should understand the advantages of these devices and make the best use of them to help to make good quality moulds. Another point, keep some clearance for the mould steel is also very critical to get correct dimension parts.

Of course, it is far more than these points to make good quality moulds, please contact us and tell us your needs, we look forward to providing our professional support for your project.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.