HanKing has an experienced team focusing on making injection moulds and molded components for medical parts, medical instruments, medical devices, medical housing and laboratory products. Customers only need to send the part drawing to us, we will deliver quality moulds or products to customer based on our staff's efforts, all the moulds and plastic parts go to our customers are qualified in dimensions, tolerance and best functionalities.

Our products cover a wide range of industries over the past few years, we have been involved in a variety of medical plastic molds and injection molding products, from connectors to adapters, from protective caps to tubes and various plastic housings, medical cases, plastic front covers, back covers, plastic buttons, etc..

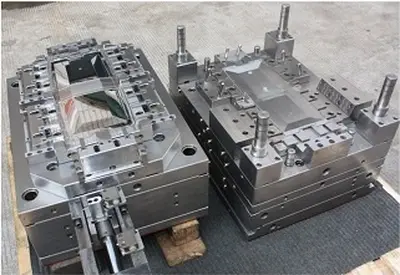

We can provide custom mold service for a single component or many plastic parts projects, whether the part is small or large, simple plastic part or complex structure component, our professional plastic mould design and engineering team will serve you the best custom mould and molding solutions.

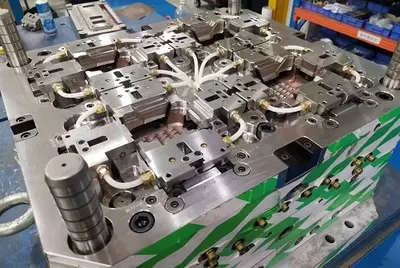

Medical device molds are precision, high-demand injection moulds, the molding process has high requirements, HanKing in medical device product development has a wealth of experience, raw materials are usually PC, ABS or PC/ABS, surface treatment is usually texture or mirror SPI A1. Therefore, improving the experience of parts and mould design is important for obtaining beautiful parts after injection molding, and mold manufacturing suppliers will need a wealth of experience.

At HanKing, you'll have a one-stop solution to save time and reduce risk. Mould design usually takes 1 week to complete, but for medical purposes, many tests are required after first of trial. HanKing has the patience and technology to provide customers with multiple mould modification and sampling.

We pursuit perfection because the quality is the life of plastic moulds, we spend time in designing medical injection molds with the highest integrity and quality. We always identify potential problems before start cutting the mold steel, and recheck all tolerances when making the mould. Whether the medical mould requires high gloss, diamond surface treatment or a more conventional surface finish, we can meet your requirements.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.