All molds for medical parts are classified as medical moulds, included disposable medical products, medical equipment internal parts and plastic housing.

As we all know, high-quality medical mould mainly depends on the mold design process. We choose the most advanced design software to analyze the mold, thoroughly identify the defects in the design and check whether the mold has warpage, weld line, shrinkage, warping, etc., improve design efficiency and create higher quality, higher precision medical mould. The design team has rich experience in optimizing the structure of plastic mold parts, avoiding solution defects before starting the mold making, saving costs and shortening the development time.

Good inspection management mechanism, equipped with CMM three-coordinate measuring equipment, two-dimensional projector and other testing equipment, etc., to achieve high precision operation and ensure the quality of plastic moulds.

HanKing Mould appoints a dedicated project engineer for customer, keep customers informed of the progress of the project such as providing weekly schedule each week, from project start to mold delivery, the entire process is transparent to customers.

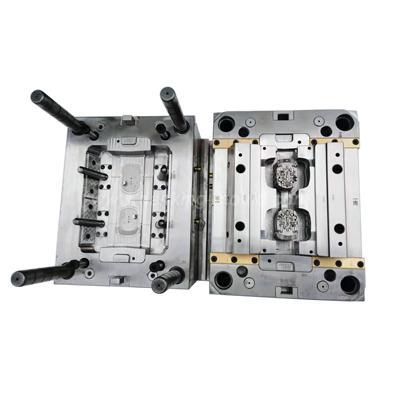

In HanKing, we can make both prototypes, validation mould, series molds, no matter the mould is a single cavity or multi cavities plastic injection mould for medical products.

The normal cavity and core steel: S136, H13, 8407, NAK80, etc..

Product material: PP, ABS, PC, HDPE, PS, PBT, PA6+ GF, POM, PC/ABS, TPE, TPU, etc..

Mould life can be 1.5 million.

The mould can be produced with a weight of 15T and a maximum size of 1M.

We have established good relations of cooperation with customers in Europe, America and Southeast Asia Through professional medical device molding service.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.