We have been manufacturing plastic precision moulds for more than ten years. With our expertise and experience, we provide valuable mold opening suggestions to our customers according to their specific needs, thus helping customers save manpower and resources.

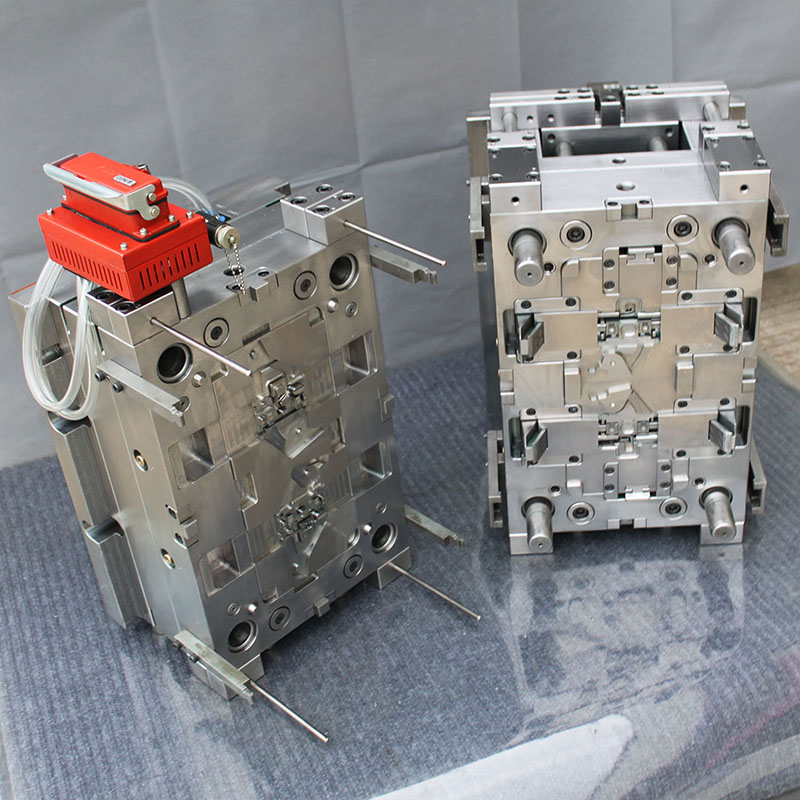

Plastic precision moulds are normally required to be short mold cycle time and long life cycle, a good toolmaker should find the best mould solution combine the specific needs of customers, the mould must be easy handling and maintenance.

In order to ensure the smooth progress of the high precision mould project, detailed mould design analysis(DFM) must be done, and if necessary, mold flow analysis is required.

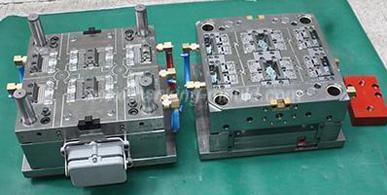

Before starting the processing, we need to communicate with the clients repeatedly, fully understand the needs of the customers, design the molds that meet the production requirements. DFM, mold design must be confirmed by customers before starting to manufacture the moulds.

Stable employees are also very important. We have a comfortable working environment: central air conditioning, dehumidification system, exhaust system and epoxy floor. Our employees and technicians have been working here for many years and this is an important factor in ensuring quality stability.

High Precision mould trial: With a special mold trial injection molding machine, qualified mold trial operator to ensure professional and on-time sampling service for customers.

In HanKing Mould, we have a complete set of high-precision measurement equipment, capable of providing full dimension FAI measurement reports.

Weekly work schedules, mould pictures, and test reports will be sent to the customers.

With reliable quality, on-time delivery and reasonable price, not only provide professional one-stop service from plastic precision mould development but also flexible service to individual molds or small batch plastic parts production. Whether the order is big or low volume, HanKing will make the best, all customers are VIP.

Precision moulding, also known as precision molding, is a manufacturing process used to create intricate and precise components or products. It involves the use of a mould or mold, which is a hollow cavity with the desired shape of the final product. The mould is typically made from steel or other durable materials.

The precision moulding process begins with the design of the mould, which is usually done using computer-aided design (CAD) software. The mould is then created using precision machining techniques such as milling or electrical discharge machining (EDM). The mould is carefully crafted to ensure that it has the exact dimensions and features required for the final product.

Once the mould is ready, the actual moulding process can begin. This usually involves injecting molten material, such as plastic or metal, into the mould cavity under high pressure. The material fills the cavity and takes the shape of the mould, replicating its intricate details and features. The high pressure ensures that the material fully fills the mould and creates a precise replica of the desired product.

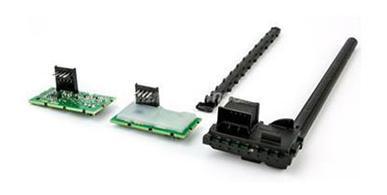

After the material has cooled and solidified inside the mould, it is ejected, and the moulding cycle starts again for the next component. Depending on the complexity of the product and the material used, additional post-processing steps may be required, such as trimming excess material, surface finishing, or assembly.

Precision moulding is commonly used in various industries, including automotive, electronics, medical devices, and consumer goods. It allows for the production of highly accurate and consistent components with tight tolerances and complex geometries. The process is efficient, repeatable, and can be automated for high-volume production.

Overall, precision moulding is a vital manufacturing process that enables the creation of intricate and precise products, contributing to various industries' advancements and innovation.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.