As one of the prototype & plastic mold makers whose goal is becoming an expert in the prototype mold making industry, HanKing Mould has experience in handling many different types of mould, including but not limited to prototype molds.

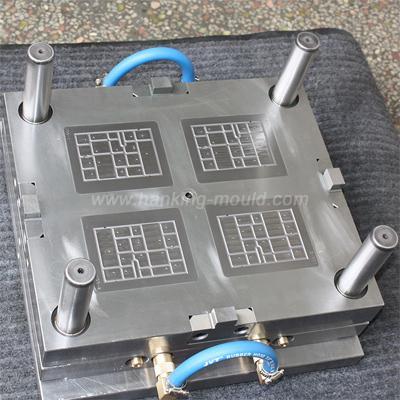

Prototype Mould is a kind of test mould before mass production mould, customer makes test mould for design verification, product structure, part function analysis or produces small lot parts for other process verification. Prototype moulds are usually different from production moulds as they are not usually intended to be used for long periods of time.

Prototype molds are also called soft moulds or fast moulds, thus the cost of prototype molds are less than serious plastic moulds, when our designer is constructing a prototype mould, the first point he should learn is the purpose of customer to make this prototype mold.

Some customers' goal is to manufacture low-cost pre-production molds that are tested and troubleshooting prior to final serious production to obtain more engineering data.

Some customers have reduced the overall product development cost of manufacturing low-cost prototype molds simply because of the low production of parts in demand.

Some clients are purposed to get fast samples or small batch quantities, for other process testing, such as electrical engineering testing, painting testing, etc.

If you are not sure if the final parts are functional ok and how to build a production mould, as a professional prototype mold maker in China we will give you professional suggestion that which mold design is high efficiency and low cost, and also HanKing provide very short lead time to save your time of product develop process.

Plastic prototype manufacturing is the process of creating a physical model or sample of a plastic product design before mass production. The plastic prototype is used to test the design and ensure that it meets the necessary requirements before beginning mass production.

The plastic prototype manufacturing process typically involves the following steps:

Design: The product design is created using Computer-Aided Design (CAD) software or other design tools.

Material selection: The appropriate plastic material for the prototype is selected based on the product's intended use and other requirements, such as durability and cost.

Prototype creation: The chosen manufacturing method is used to create the physical prototype. There are several methods for plastic prototype manufacturing, including 3D printing, injection molding, vacuum forming, and CNC machining. The selection of the appropriate method depends on the complexity of the design, required accuracy, and the quantity of prototypes needed.

Testing and evaluation: The plastic prototype is tested and evaluated for its functionality, durability, and other performance metrics. Feedback is collected to identify design flaws and areas for improvement.

Refinement: Based on the feedback received during testing and evaluation, the product design is refined to address any issues or concerns.

Production: Once the plastic prototype has been thoroughly tested and refined, it is ready for mass production.

Overall, the plastic prototype manufacturing process is an essential step in product development, as it helps to identify and address design flaws and manufacturing challenges before mass production begins.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.