We'd like to introduce the difference about injection molding and extrusion. These two processes are crucial in the realm of manufacturing, each with its unique set of characteristics and advantages. Let's dive into the intricacies of injection molding and extrusion to understand the key differences between them.

Injection Molding

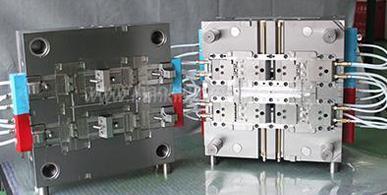

Injection molding is a widely-used manufacturing process that involves injecting molten material into a mold to create a specific shape. This method is known for its precision and efficiency, making it ideal for producing intricate and complex parts with high accuracy.

One of the key advantages of injection molding is its ability to mold parts with detailed features and tight tolerances. This process is commonly used in the production of plastic components for various industries, including automotive, electronics, and consumer goods.

For example, plastic containers, automotive dashboards, and medical devices are often manufactured using injection molding due to its ability to produce high-quality, consistent parts at a rapid pace.

When considering injection molding for a project, factors such as material selection, mold design, and production volume should be taken into account to ensure optimal results.

Extrusion is another popular manufacturing process that involves shaping materials by forcing them through a die to create a continuous profile. This method is commonly used for producing long, uniform shapes such as pipes, tubes, and sheets.

One of the primary advantages of extrusion is its ability to create complex shapes with consistent cross-sections. This process is often utilized in industries such as construction, packaging, and food production for manufacturing a wide range of products.

Examples of products made through extrusion include PVC pipes, aluminum window frames, and plastic film packaging. Extrusion offers cost-effective production solutions for items that require a continuous length or consistent shape.

When choosing extrusion for a project, considerations such as material compatibility, die design, and production speed should be taken into consideration to ensure efficient and accurate results.

While injection molding and extrusion are both essential manufacturing processes, they differ in several key aspects that impact their suitability for specific projects.

Material Feed and Shaping Method: Injection molding involves injecting molten material into a closed mold cavity, allowing for precise shaping and detailing of parts. In contrast, extrusion involves pushing materials through a die to create a continuous profile, making it ideal for producing long, uniform shapes.

Design Flexibility and Complexity: Injection molding offers greater design flexibility and complexity, making it suitable for intricate parts with detailed features. Extrusion, on the other hand, is better suited for products with consistent cross-sections and continuous lengths.

Production Efficiency and Cost Considerations: Injection molding is often more efficient for producing small to medium-sized batches of complex parts, while extrusion excels in producing large volumes of uniform shapes at a lower cost per unit.

Suitability for Different Types of Products: Injection molding is preferred for parts with high precision and detailed features, while extrusion is ideal for products that require consistent shapes and lengths, such as pipes, tubes, and profiles.

Let's take a look at some real-world examples of companies utilizing injection molding and extrusion for their manufacturing processes.

Injection Molding: Company X specializes in producing customized plastic components for the automotive industry using injection molding. Their precision molding capabilities allow them to manufacture complex parts with high accuracy and repeatability.

Extrusion: Company Y is a leading manufacturer of PVC pipes for the construction industry, utilizing extrusion to produce long, uniform pipe sections at a cost-effective rate. Their efficient extrusion process ensures high-quality pipes for various construction projects.

In conclusion, understanding the key differences between injection molding and extrusion is essential for choosing the right manufacturing process for each project. While injection molding is ideal for producing complex parts with high precision, extrusion excels in creating continuous shapes at a lower cost per unit.

Whether you're looking to manufacture intricate components or uniform profiles, selecting the appropriate molding method can make a significant impact on the quality, efficiency, and cost-effectiveness of your production process. So, next time you embark on a manufacturing project, remember to consider the nuances between injection molding and extrusion to ensure optimal results!

For injection mold manufacturing service, please contact yoyo@hanking-mould.com

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China