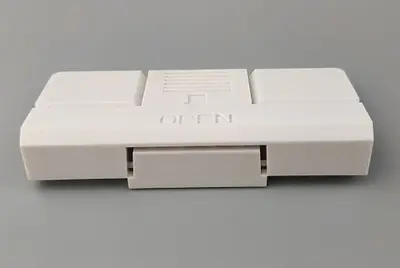

I. Definition and Characteristics of Silver Streaks

Silver streaks, also known as silver marks, appear as burst blister-like lines on the surface of injection molded parts. They typically form arrow-shaped patterns pointing toward the gate, indicating flow direction during molding. These defects compromise surface aesthetics and may signal underlying process issues.

II. Root Causes of Silver Streaks

2.1 Equipment-Related Factors

Nozzle & Barrel Issues:

Small nozzle holes, material leakage/drawing at the nozzle, or obstructions in the barrel or nozzle cause melt to decompose due to frictional heat from high-speed flow.

Worn barrels/screws or dead-end areas in screw caps/collars lead to prolonged heating and material decomposition.

Heating & Screw Design Flaws:

Malfunctioning heating systems (e.g., thermocouples, coils) cause overheating and decomposition.

Improper screw design induces air entrapment or material degradation.

2.2 Mold Design and Conditions

Flow and Venting Defects:

Poor gate location, small gates, asymmetrical runner layouts, or inadequate cooling create uneven mold temperatures, blocking air escape and impeding melt flow.

Sharp mold corners generate high shear forces, decomposing the melt and forming silver streaks.

Venting Inefficiencies:

Lack of or blocked vents, improper vent placement, or insufficient clearances (e.g., around inserts/pins) trap air in the cavity during filling.

Surface and Contamination Issues:

Rough mold surfaces increase frictional resistance, causing local overheating and plastic decomposition.

Oil, water, or air leakage into the cavity from mold components stains the part surface.

2.3 Molding Process Flaws

Temperature Mismanagement:

Excessive material temperature (barrel overheating or imbalanced heating) causes decomposition. Premature melting in the feeding section blocks air venting through the feed port.

Injection Speed Imbalances:

Too-fast speeds induce high shear forces, decomposing the melt and generating gas. Too-slow speeds result in insufficient filling and surface density.

Material Handling Issues:

Insufficient material supply, large feeding buffers, or low material/mold temperatures reduce melt fluidity, creating voids and streaks.

Low screw backpressure and high rotation speeds push air into the barrel front during pre-molding.

2.4 Material-Related Causes

Contamination and Moisture:

Dust or foreign particles in raw materials entrain air during melting, leading to decomposition and streaks.

Excessively moist materials (not fully dried) or high water content/porosity in the resin cause surface defects.

Recycled Material Misuse:

Overuse of recycled sprue (e.g., >20% mix with new material) or excessive recycling cycles degrade material quality.

Additive Degradation:

Decomposition of additives in the material generates gases that form silver streaks during molding.

III. Systematic Approach to Resolving Silver Streaks

3.1 Equipment Maintenance and Adjustment

Regularly inspect nozzles, barrels, and screws for wear; clean obstructions and replace faulty heating elements.

Optimize screw design to minimize dead ends and improve material flow.

3.2 Mold Modification and Venting

Revise gate and runner layouts for balanced flow; enlarge gates and runners if necessary.

Add or clean vents, ensuring proper placement (e.g., at melt front end points) and sufficient clearance around mold components.

Polish rough mold surfaces to reduce friction and heat generation.

3.3 Process Parameter Tuning

Lower barrel temperatures step-by-step to prevent overheating; ensure uniform heating across all zones.

Adjust injection speed to balance filling efficiency and shear stress (slower speeds for heat-sensitive materials).

Optimize screw backpressure and rotation speed to minimize air entrainment during material feeding.

3.4 Material Quality Control

Thoroughly clean raw materials to remove dust and contaminants; inspect recycled material ratios (limit to ≤20% of new material).

Pre-dry hygroscopic materials according to specification (e.g., nylon requires prolonged drying at elevated temperatures).

Evaluate additive compatibility and stability to prevent decomposition during processing.

Silver streaks in plastic injection molding require a multi-faceted approach, addressing equipment, mold, process, and material factors to ensure defect-free production.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China