Understanding the Types: 1K vs 2K Injection Molding

Injection molding comes in different types, each serving a specific purpose in creating toys, tools, and other products. Let's explore the differences between 1K and 2K injection molding to understand how each method works.

What is 1K Injection Molding?

1K injection molding involves using one type of material to produce a product. This method is commonly used for making simple plastic parts that do not require multiple materials or colors. For example, a single-color plastic part could be made using 1K injection molding.

What is 2K Injection Molding?

On the other hand, 2K injection molding, also known as dual-component molding, double shot injection mould, uses two different materials or colors to create a single product. This method is ideal for making toys with intricate designs or multiple colors. Imagine a toy with a colorful body and wheels; 2K injection molding makes it possible by combining different materials in one process.

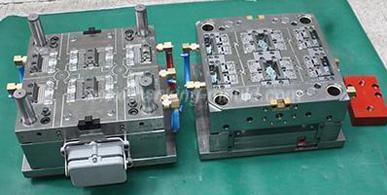

Creating the Perfect Mold

In injection molding, the mold plays a crucial role in shaping the final product. Let's dive into the world of mold design and precision engineering to understand how it all comes together.

The Art of Mold Design

Imagine designing a mold is like solving a puzzle. Each piece must fit perfectly to create a flawless product. Engineers carefully plan and create molds that will produce toys and parts that are just right.

Precision is Key

When it comes to mold design, precision is essential. Engineers use precise measurements and calculations to ensure that every mold works flawlessly every time. This attention to detail guarantees that each toy or part fits perfectly, making sure that every piece is just right.

Choosing the Right Material

When it comes to making toys and other products through injection molding, the material you choose is crucial. Different types of plastic can greatly impact the quality and durability of the final product. For example, some toys need to be flexible and bendable, while others need to be sturdy and strong. The material used determines these characteristics, making it an essential decision in the manufacturing process.

Picking the Perfect Plastic

Imagine a squishy toy that needs to be soft and squeezable. To achieve this, a soft plastic material would be the ideal choice. On the other hand, building blocks that require strength and rigidity would be made from a hard plastic. By selecting the right type of plastic for each product, manufacturers ensure that the toys meet the specific requirements for play and durability.

Making Things Better and Faster

Do you ever get excited about a new toy or game and can't wait to play with it? Well, using the right type of injection molding can help make those toys reach you faster! When companies make toys or parts using efficient manufacturing methods, they can produce them quickly and get them on store shelves in no time. This means you can enjoy your new toys sooner and have more fun playing with them!

Smart Manufacturing Saves Resources

Not only does using the right injection molding technique make things faster, but it also helps save resources. Efficient production methods use less energy and material to make the same number of toys or parts. This is good for the environment because it reduces waste and saves valuable resources. So, by making things better and faster, companies are not only making customers happy but also helping to protect our planet!

Introduction to Injection Molding

This section will introduce readers to the basics of injection molding, a popular method used to make plastic parts for toys, tools, and more.

What is Injection Molding?

Injection molding is a cool way to make all sorts of things out of plastic. Imagine melting your favorite toy and pouring it into a special mold. When the plastic cools down, you can pop out a brand new toy that looks just like the original! That's how injection molding works – melting plastic and injecting it into molds to create different shapes like cars, dolls, or even kitchen tools.

Why is Injection Molding Important?

Injection molding is super important because it helps make a lot of the things we use every day. From the toys we play with to the tools we use, injection molding is a key part of creating new products. It's like magic – turning melted plastic into fun toys and useful tools!

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China