1. Rubber injection: Rubber injection molding is a kind of production method that the rubber material is injected into the model directly from the barrel. The advantages of rubber injection molding are: although it is batch operation, its molding cycle is short, and its production efficiency is high; it cancels the preparation process of embryo material, achieving low labor intensity and excellent product quality.

2. Plastic injection: Plastic injection is a method of plastic products. The molten plastic is injected into the plastic product mould by pressure, and then cooling and forming it, finally, the desired plastic parts are obtained. There are special machines for injection molding: injection molding machine. The most commonly used plastic at present is polystyrene.

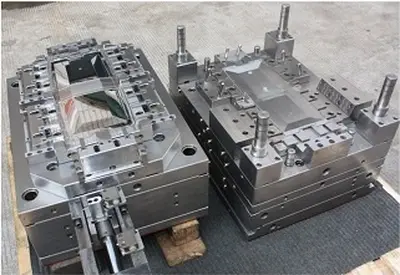

3. Injection molding: the shape obtained is often the final product, and no other processing is required before installation or being used as the final product. Many details, such as bulges, ribs, and threads, can be molded in one-step injection molding.

HanKing Mold is a customized injection molding manufacturer in China, welcome to inquiry and order.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China