The development of mobile phone shell products needs to go through the process of product structure design, mold development and design, injection molding production, spray printing and so on. Each link will affect the appearance of mobile phone shell. HANKING MOULD ENGINEERING LTD. has some suggestions on what issues need to be paid attention to during the injection molding process of mobile phone shell molds. We hope these can be helpful to you.

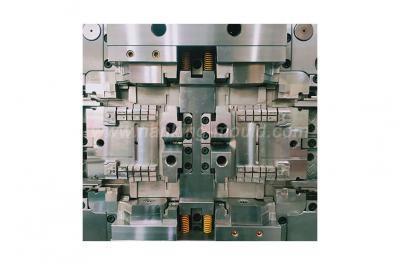

The injection mold design of the mobile phone shell must take into account the structure and assembly of the product. In addition, the ejection of the product and its waterway arrangement and the distribution of the glue inlet must be considered in the manufacturing process. The following briefly introduces the design attention points of the product ribs, hooks, and nut holes.

When using PC or ABS+PC, the thickness of rib is not more than 0.6 times the thickness of the phone shell itself. The aspect ratio cannot exceed 3 to 5 times of its own thickness.

The draft angle of the mobile phone shell mold is approximately 0.5 to 1.0 degrees.

The space between the two ribs is more than 3 times the wall thickness.

The card entry specification of the hook is generally 0.5 mm to 0.8 mm.

The hook moves down 0.2 mm from the parting surface, which is beneficial for the processing of the mobile phone shell mold.

The occlusal surface of the hook and the card slot has a gap of 0.05mm for easy mold repair in the future.

A space of 0.3 mm is reserved at the top of the slot at the bottom of the hook as a resilient space for the deformation of the hook.

The other mating surfaces should leave a gap of 0.1 to 0.2 mm.

The oblique guide post of the hook has to leave a stroke arrangement of 6 to 8 mm.

The tip of the hook has a 0.1 mm arc for easy disassembly and assembly.

A 2-degree draft can be left at the mating surfaces of the hooks as a disassembly angle.

The guide R angle at the bottom of the slot improves the compressive strength, so the inclination angle of the area with different meat thickness is used as the conversion area.

Mobile phone shells are usually molded from PC or PC+ABS materials. Due to the poor fluidity of PC, the process usually uses high mold temperature and high material temperature to fill; The gate used is usually a point gate. When filling, it is necessary to use graded injection molding to find the gate position and the V-P (injection-holding pressure) switching position, which will be of great help in solving abnormalities such as gate gas marks and underfill flash.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China