With the development of intelligence and miniaturization of electronic products, the precision of products is getting higher and higher, and the application of 3 plate mold I / M process is becoming more and more common. Traditional manual or robot assisted implantation is not efficient, so the pull type I / M process is becoming more and more popular.

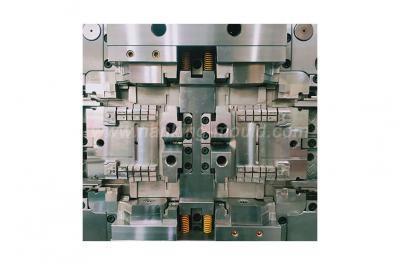

There are three types of commonly used 3 plate mold: the first one is between the stripping plate and the female template; the second one is between the stripping plate and the upper fixed plate; and the third one is between the female template and the male template.

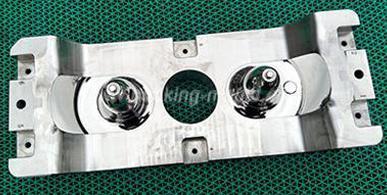

When the male mold side is initially pulled by the injection mold maker, there is no connection and obstruction between the stripping plate and the female template due to the installation of the shutter between the male and female templates, and there is no connection and obstruction between the stripper plate and the female template (in most cases, the small pull rod is also equipped with a spring). At this time, the stripper plate and the female template are first separated under the pull, and the female template moves backward with the male template, moving to the set distance (greater than the length of the head), which is blocked by the small pull rod limit block. As the female template continues to move backward along the side of the injection molding machine, the small pull rod is also driven. It drives the stripper plate to move for a set distance (usually 5mm), so as to lower the material head. After the set distance is moved, the small pull rod and the female template stop moving.

The side of the injection moulder continues to move backward from the moving side, and the tensile force increases continuously, which exceeds the locking force of the shutter. The female formwork and the male formwork are separated, and stop when they are separated to the set distance.

Under the push of the ejector, the ejector plate drives the ejector mechanism (ejector pin, slant bit, etc.) to start the ejection action, and ejects the finished products (automatically falling or taken away by the manipulator).

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China