1. The injection molding process of plastic molds is long and the processing time is short. For injection molded parts, many of them are complete products that are matched with other parts. Because of the high requirements on the shape or dimensional accuracy of the product, and because of the different characteristics of the plastic materials, mold trials and modifications are required.

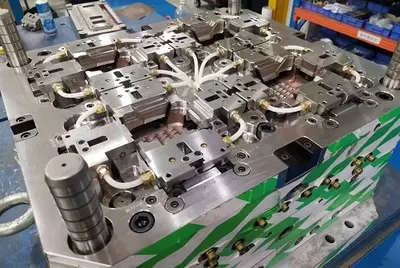

2. Plastic mold injection processing requires professional division of labor. Plastic injection molds require a lot of parts, ranging from mold bases to small thimbles. These are not only completed by one manufacturer, but the processing technology is complicated, and professional plastic mould makers are required to perform plastic mold injection processing.

3. Off-site design and off-site processing. Plastic mold processing is not the ultimate goal. Customers propose perfect product designs. Plastic mold processing manufacturers design and process plastic molds according to user requirements.

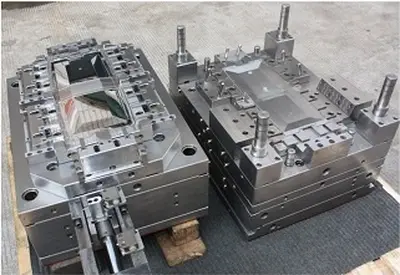

4. The cavity and core are three-dimensional. The external and internal shapes of plastic parts are directly formed by the cavity and core. These complex three-dimensional profiles are difficult to process, which not only requires high technical level of workers, many auxiliary fixtures, many tools, and long processing cycles.

5. High precision and quality requirements, long service life. The injection molding of high-precision plastic molds adopts inlaid or fully assembled structure, which requires very high processing accuracy of plastic mold parts.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China