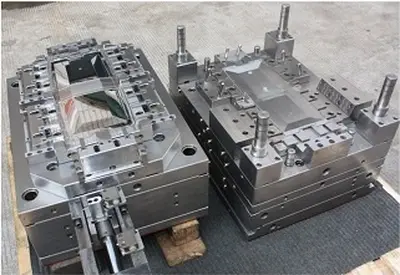

The service life of precision plastic molds is directly related to the quality of the mold itself, which is known for all. But the service life of precision plastic molds is also related to other aspects.

The quality of precision plastic molds is mainly related to design, material selection, processing, assembly, etc. From a design perspective, the main considerations are:

(1) The size of the mold base, the wall thickness of the cavity; the relationship between the service life and the manufacturing cost, and the impact of the size of the injection molding machine on the investment cost and production cost.

(2) The strength of the insert and the reliability of its placement.

(3) Try to avoid individual parts or a certain position in the cavity from becoming a weak link.

(4) The guide post plays an important role in the process of moving the mold, so consider its strength and wear resistance. Other material selection, processing, and assembly mainly consider the contradictory relationship between cost and quality. The following mainly talks about the relationship between the clamping mechanism and the service life of precision plastic molds.

(5) Before the precision plastic mold is opened, the toggle lever type has not released the clamping force, especially when the core is overloaded, the core has not recovered, and the plastic has cooled, so the friction between the metal and the plastic greatly increases the core wear.

(6) When the mold is opened, the toggle lever type will produce vibration due to the sudden release of the clamping force, which will aggravate the damage of some stressed parts.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China