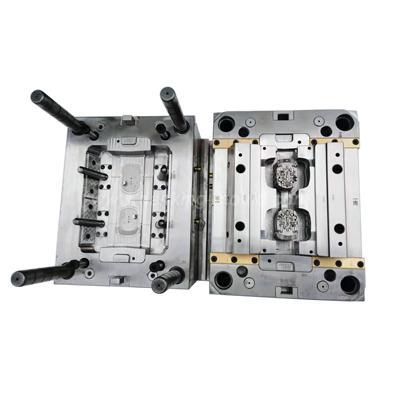

Finally, a plastic injection tooling was made. Only after a thousand entreaties does it make! Next, we have to test the effectiveness of the mold, that is, mold trial. Then put it into production, and how to maintain the mold during production, so that the mold can be in a better working condition and let us reap the greatest benefits?

When testing the plastic injection tooling, pay attention to whether the opening and closing of the mold is smooth, and whether the ejection is smooth. Secondly, pay attention to the gate position and injection method of the mold as well as the gate size and cavity size to select the appropriate pressure, speed, and material volume for injection molding. When the mold heats up, carefully check whether all the matching parts of the mold are too hard, and then confirm the bonding line and exhaust. After the product is full, ask the quality personnel to confirm the size and appearance.

During the production process of plastic injection tooling, check the mold settings and safety devices so that the operators can understand the problems that may occur in the process. After the production is completed, the lower mold or standby needs to take necessary measures for the machine and mold.

The plastic injection tooling must be maintained when the mold is not in production. First, check the mold and determine the maintenance method. If you need to disassemble the parts, first check whether there is a clear mark. After the maintenance of the parts is completed, the assembly must be matched and seated. After the assembly is completed, the sequence of the mold must be confirmed. Pay attention to the careful inspection and confirmation of the first piece after each maintenance. Production can be continued after the quality personnel confirm OK.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China