HanKing Mould Enginering Ltd. is one of the medical device injection molding companies with more than ten years of manufacturing experience. For the production of syringe molds, a complete set of equipment systems has been introduced. It is precisely because of its mature development technology and level that it has provided nearly 100 sets of syringe mold equipment for different countries. The syringe consists of three molds: outer cylinder, push rod, and rubber stopper.

At the same time, we can also produce various medical molds, such as PET test tube molds and utensil molds. Because we have a perfect hot runner system for PET and PS injection. At the same time, because of our high-precision processing equipment, technology and management, we can successfully produce such multi-cavity molds.

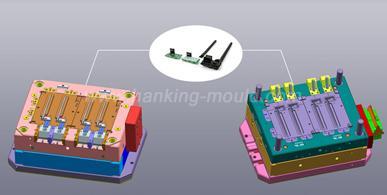

The number of cavities is one out of sixteen. Of course, one out of twenty-four or one out of seven-two can be made, and one out of one hundred and twenty-eight is also possible. The life of the mold will be selected according to the needs of customers with different grades and different life steel materials, generally Stavax Esrls (s-136) = 420ss, manufactured by ASSAB (ASSAB), its hardness reaches HRC45-52 after quenching and tempering. It is made of stainless steel and tempered steel. The cycle period is generally about two or three seconds. The gate method is usually the hot runner point gate, and the ejection method is the ejector plate. The outer cylinder and push rod of the product are generally PP or PE. The rubber plug is generally TPE or medical PVC (if PVC is used, we don't recommend using thermal sleeve). The steel materials of spare parts will adopt D-M-E metric standard or SINO standard. The steel material of the formwork is generally made by SC45 China. The hot runner is usually Anole standard hot runner system, which uses German heating system and Anole standard series temperature control box. The core and cavity steel material will be selected according to the different requirements of customers. The slider usually adopts the Luer interface slider system. If the insert/slider steel material is less than 10KG, H13 (DIN1.2344) is used, and its hardness reaches HRC42- 45. If it is greater than 10KG, use the same steel material as the core cavity. The acceptance standard is generally based on drawings as the acceptance standard or the actual sample as the acceptance standard.

HanKing Mould Enginering Ltd. not only provides you with the best quality molds, but also provides you with the best pre-sales, in-sales and after-sales services, so that you have no worries. If you have any needs, please call us for consultation!

In the high-precision plastic mold industry such as medical molds, HanKing Mould Enginering Ltd. has many years of manufacturing experience, advanced equipment and systems, and an excellent team. It can make molds with different cavities according to customer needs.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China