Prevention and Control of Flash in Injection Molded Parts: Core Points and Practical Operation

In plastic injection molding, flash on injection molded parts has long been a persistent challenge for manufacturers. Flash not only impairs product appearance but also causes dimensional deviations, assembly difficulties, and even reduces overall product performance and service life. Mastering the core points of flash prevention and control, along with effective practical measures, is crucial for improving production efficiency and product quality—especially in plastic injection mold manufacturing, where precision and consistency directly determine market competitiveness.

1. Causes of Flash in Injection Molded Parts

To effectively prevent and control flash, it is essential to first identify its root causes. Flash formation is closely related to three key factors: mold conditions, injection process parameters, and raw material properties—all of which are central to

plastic injection mold manufacturing quality control.

1.1 Mold-Related Factors

不合理的分型面设计 / Inappropriate Parting Surface Design: The parting surface is a critical component in mold design. Poorly positioned or poorly fitted parting surfaces create gaps, allowing molten plastic to overflow under injection pressure.

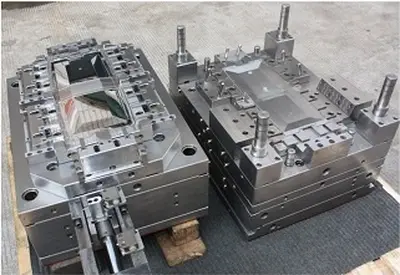

Insufficient Mold Precision or Wear: Inaccurate mold processing or prolonged use leading to component wear increases fit gaps between mold parts. During injection, molten plastic seeps through these gaps, forming flash.

Poor Mold Sealing: Defects in mold assembly (e.g., loose fasteners) or damage to sealing components compromise the mold’s ability to resist injection pressure, resulting in flash.

1.2 Injection Process Factors

Excessive Injection Pressure or Speed: High pressure and speed cause molten plastic to impact the mold cavity with excessive force, exceeding the mold’s design tolerance and leading to overflow.

Overlong Holding Pressure Time: Prolonged holding pressure results in over-filling of the mold cavity, increasing the risk of flash as plastic is forced into gaps.

Inadequate Cooling Time: Insufficient cooling causes incomplete solidification of the plastic, reducing its structural integrity and making it more prone to overflow under pressure.

1.3 Raw Material Factors

Excessive Plastic Fluidity: Plastics with overly high fluidity easily fill tiny gaps in the mold during injection, forming flash. This is a key consideration in material selection for plastic injection mold manufacturing, where matching material properties to mold design is critical.

2. Core Points for Flash Prevention and Control

Flash prevention and control require a systematic approach, integrating mold design, process optimization, and material selection—all foundational to

high-quality plastic injection mold manufacturing.

2.1 Mold Design and Maintenance

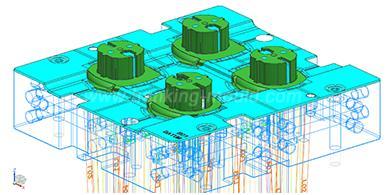

Rational Parting Surface Design: Design the parting surface based on product shape, structure, and demolding requirements to ensure precise positioning and tight fitting. For complex parts, adopt multi-parting surface designs to enhance mold sealing and stability.

Improve Mold Precision: Strictly control machining precision during mold production, ensuring fit gaps between components are within acceptable limits. Regularly maintain and repair molds, replacing worn parts to preserve their performance—an indispensable practice in plastic injection mold manufacturing to extend mold life and reduce defects.

Enhance Mold Sealing: Check and tighten mold fasteners regularly. Repair or replace damaged sealing components to prevent pressure-induced gaps.

2.2 Optimization of Injection Process Parameters

Adjust Injection Pressure and Speed: Tailor pressure and speed to plastic type, product shape, and size. Avoid excessively high values; use trial runs to determine the optimal combination that ensures full filling without overflow.

Control Holding Pressure and Cooling Time: Set holding pressure time based on product thickness—avoid overlong durations. Ensure sufficient cooling time to allow complete solidification of the plastic, balancing dimensional stability and production efficiency.

Ensure Proper Ventilation: Optimize the mold’s ventilation system to release trapped air and gas, reducing pressure buildup that can force plastic into gaps.

2.3 Selection of Suitable Raw Materials

Consider Plastic Fluidity: Choose plastics with moderate fluidity matching the product’s molding requirements. For parts prone to flash, avoid materials with excessively high fluidity to minimize the risk of mold gap filling.

Verify Material Quality: Ensure raw materials meet specified performance standards (e.g., viscosity, melting point). Avoid using degraded or contaminated plastics, which can alter fluidity and cause flash.

3. Practical Operation for Flash Prevention and Control

Translating core points into actionable steps is key to resolving flash issues, with specific practices aligned to plastic injection mold manufacturing workflows.

3.1 Practical Mold Measures

Parting Surface Treatment: Before mold installation and use, inspect and clean the parting surface to remove impurities and ensure flatness. Use abrasive paste for precision grinding to improve fitting tightness. Regularly check for wear and repair or replace the parting surface as needed.

Systematic Mold Maintenance: Establish a comprehensive maintenance system. Clean the mold thoroughly after each production run to remove residual plastic and debris. Lubricate guide components and ejection mechanisms, and apply anti-rust treatment to prevent corrosion—critical for sustaining mold performance in plastic injection mold manufacturing.

3.2 Practical Injection Process Adjustments

Parameter Debugging via Trial Runs: Conduct trial injections before mass production. Start with low pressure, speed, and holding time, then gradually adjust based on flash presence and product quality until the optimal parameter combination is achieved.

Real-Time Process Monitoring: Use advanced monitoring equipment (e.g., pressure sensors, temperature sensors) to track process parameters in real time. Adjust immediately if abnormalities are detected, ensuring stable production and minimizing flash risks.

3.3 Practical Raw Material Management

Strict Quality Inspection: Conduct rigorous inspections of incoming raw materials, focusing on fluidity, viscosity, and other key indicators. Reject materials that do not meet requirements to eliminate flash risks at the source.

Proper Storage: Store raw materials in controlled environments to prevent moisture absorption, degradation, or contamination. Maintain stable material properties to ensure consistent molding performance—an often-overlooked aspect of flash prevention in plastic injection mold manufacturing.

4. Conclusion

Preventing and controlling flash in injection molded parts is a systematic project that requires integrated efforts across mold design, process optimization, and raw material management. In plastic injection mold manufacturing, where precision and efficiency are paramount, mastering these strategies not only resolves flash issues but also enhances overall production quality and profitability. Manufacturers should continuously summarize experience, refine techniques, and adapt to evolving market demands and production environments to maintain a competitive edge.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China