Injection molding of household mould is a method of injection and molding. It has advantages of fast production speed, high efficiency, automatic operation, design varieties, simple to complex shapes, large to small sizes, accurate product sizes, easy to update products and complex shapes. Injection molding is suitable for large-scale production and products with complex shape and other molding processing fields.

At a certain temperature, the completely melted plastic material is stirred by a screw, injected into the mold cavity with high pressure, cooled and solidified, and then the molded product is obtained. This method is suitable for the mass production of complex shape parts and is one of the important processing methods.

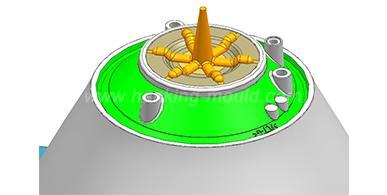

Molding equipment and moulds for family mold injection molding

Barrel temperature:

The temperature to be controlled in the injection molding process includes barrel temperature, nozzle temperature and mold temperature. The first two temperatures mainly affect the plasticization and flow of plastics, while the second one mainly affects the flow and cooling of plastics. Each kind of plastic has different flow temperature. For the same kind of plastic, the flow temperature and decomposition temperature are different due to different sources or brands. This lies in different average molecular weight and molecular weight distribution. The plasticization process of plastic in different types of injection machines is different, so the selection of barrel temperature is also different.

Nozzle temperature:

The temperature of the nozzle is usually slightly lower than the maximum temperature of the barrel, which is to prevent the possible salivation of the molten material in the through nozzle. The temperature of the nozzle should not be too low, otherwise, the nozzle will be blocked due to the early setting of the melt, or the performance of the product will be affected due to the early setting material injected into the mold cavity.

Mold temperature:

Mold temperature has a great influence on the internal performance and apparent quality of products. The mold temperature depends on the crystallinity of the plastic, the size and structure of the product, performance requirements, and other process conditions (melt temperature, injection speed, injection pressure, molding cycle, etc.).

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China