Mold is an important basic process forming equipment in industrial production, and is often referred to as the "mother of industry". With the rapid development of China's automobile industry, the automobile mould has become the most important part of the mould industry in China, and the scale of the industry continues to expand. Driven by China's automobile lightweight policy, the lightweight development of automobile is an inevitable trend, which will effectively promote the development of plastic injection mold makers in China.

According to statistics, more than 95% of automobile parts need to rely on car parts mold for mass processing and manufacturing. In the development of a new car, approximately 20,000 automobile parts are needed, including sheet metal parts, die-casting parts, stamping parts, plastic parts, electronic vitality parts. In the process of R&D and manufacturing of these parts, a large number of molds and fixtures are required, of which the demand for molds is the largest.

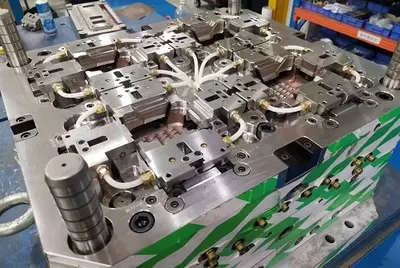

From the perspective of the material of automobile moulds, it can be mainly divided into metal molds, plastic molds and inorganic non-metal molds. At present, China's mould manufacturing is still dominated by metal molds. With the need for environmental protection and energy saving, lightweight automobile has become one of the main trends in the world's automobile design development, and the injection mould is widely used due to its lighter weight.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China