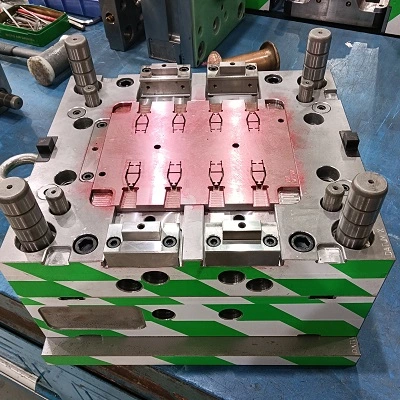

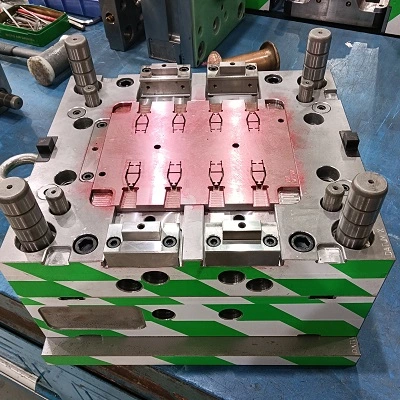

Plastic injection mould parts

Custom injection mold making and plastic parts injection molding service

Part structure optimization and mold design

Plastic mould tooling making

Injection molding production

Secondary process and assembly

Application: Plastic components, Plastic cases, Plastic housings, Plastic Enclosures.

Plastic material: ABS, PC, PP, PA, POM, HDPE, PPE, PMMA, TPE, TPU, PPS, SAN, etc.

Surface finish: Polish, Glossy, Painting, Silk Print, Texture, Soft rubber Painting.

Color: Pantone color, RAL color.

Advantages: Competitive price, fast lead time, free design, quality assurance.

Inspection: IQC, IPQC, OQC.

Tolerance: 0.01-0.02mm

Place of Origin: China plastic parts

Lead time: Mold making 3-4 weeks, production 3-15 days depends on quantities.

Injection mould process:

RFQ-Order-Product analysis-Moldflow-Mold design-Steel and material purchase-Rough machining-Mold base process-Mold cavity process-measurement-assembly-testing

Injection tooling making machine in HanKing Mould

EDM machine 5 sets

Wirecut machine 3 sets

CNC machine 6 sets

Milling machine 4 sets

Grinding machine 6 sets

2D measurement 2 sets

3D measurement 1 sets

Injection machine 17 sets

Injection molding machine Haitian, YIZUMI, JSW, total 17 sets include a vertical injection machine and a two shot screw can produce doube color plastic parts.

We make mould making structure analysis free for customers, contact HanKing Mould right away, 24 hours we can send feedback.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China