Insert Molding in Injection Molding: Principles, Processes, and Applications

Insert molding is an important composite molding technology in injection processing. It involves pre-placing heterogeneous inserts (such as metal, ceramic, or glass) into a mold, then injecting molten plastic to complete coating and bonding, ultimately forming an integrated product with the characteristics of different materials. This process breaks the performance limitations of single plastic materials and is widely used in electronics, automotive, home appliance and other industries, becoming a key means to improve product structural strength and functional integration.

1. Core Principles of Insert Molding

The essence of

insert molding is "precision compounding of heterogeneous materials", with the core logic centered on three links: positioning, coating, and bonding.

Precise Positioning: Inserts must be fixed by positioning mechanisms in the mold to ensure no displacement or inclination during injection molding, providing an accurate benchmark for subsequent bonding.

Full Coating: After molten plastic is injected into the mold, it fully coats the insert surface and fills the gaps around the insert using its fluidity.

Firm Bonding: During the cooling and solidification stage, the plastic and insert form a strong bond through mechanical interlocking (such as grooves or threads on the insert surface) or intermolecular forces, achieving functional complementarity of the two materials.

2. Key Process Flow of Insert Molding

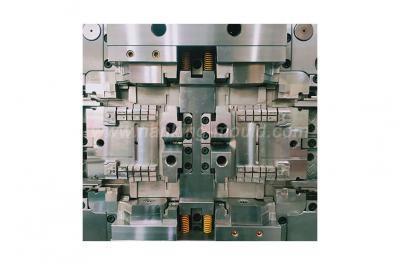

The insert molding process requires strict control of precision in each link to avoid problems such as weak bonding and product defects. The core steps are as follows:

2.1 Insert Pretreatment

Clean, degrease, and rust-proof the inserts. Some metal inserts require surface roughening or electroplating to enhance bonding force with plastic.

2.2 Insert Positioning

Accurately place the pretreated inserts into positioning pins, card slots, or other mechanisms in the mold, ensuring the position tolerance is controlled within 0.02-0.05mm.

2.3 Mold Clamping and Injection

After the mold is closed, inject molten plastic according to the set temperature and pressure parameters. The injection pressure must be adapted to the insert material to avoid damaging the insert or causing plastic overflow.

2.4 Cooling and Solidification

Set a reasonable cooling time based on the difference in thermal expansion coefficients between the plastic and the insert, preventing internal stress or cracking due to uneven shrinkage.

2.5 Demolding and Post-Processing

After the product is demolded, remove excess parts such as gates and flash. Conduct appearance inspection and bonding strength testing if necessary.

3. Common Insert Types and Application Scenarios

The material and structure of inserts should be selected according to product functional requirements. Different types of inserts correspond to different application scenarios:

3.1 Metal Inserts

Mainly made of copper, steel, aluminum, etc., common forms include threaded columns, nuts, and bushings. They are used to improve the connection strength and wear resistance of products. Typical applications include fixing nuts for home appliance casings and mounting buckles for automotive interiors.

3.2 Ceramic/Glass Inserts

With high temperature resistance and strong insulation, they are mostly used for insulation packaging of electronic components and structural parts in high-temperature environments.

3.3 Plastic Inserts

Made of reinforced plastic or special plastic, they are used to achieve functional complementarity of different plastic materials, such as composite seals with hard plastic inserts and soft plastic bodies.

3.4 Other Inserts

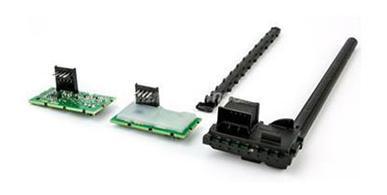

Including functional inserts such as magnetic materials, optical fibers, and sensors, which are used to endow products with special functions such as magnetic control and signal transmission, such as magnetic positioning inserts in smart devices.

4. Technical Key Points and Advantages of Insert Molding

4.1 Core Technical Control Points

Positioning Precision: The insert positioning error must be controlled at the micron level; otherwise, it will lead to poor product assembly or bonding failure. Common positioning methods include mechanical positioning and vacuum adsorption positioning.

Material Compatibility: Match the thermal expansion coefficients of plastic and insert to avoid cracking due to shrinkage differences during cooling. For example, aluminum alloy with an expansion coefficient close to that of plastic can be used for metal inserts.

Injection Parameter Optimization: Adjust the molten plastic temperature according to the heat resistance of the insert. The injection speed should not be too fast to prevent insert displacement or plastic decomposition.

4.2 Core Process Advantages

Integrated Molding: No subsequent assembly processes are required, reducing production links, improving production efficiency, and reducing assembly errors.

Functional Composite: Combine the molding flexibility of plastic with the special properties of inserts to achieve functional combinations such as "plastic's light weight + metal's sturdiness" and "plastic's insulation + ceramic's high temperature resistance".

Structural Lightweight: Compared with all-metal products, insert molding can reduce material usage while ensuring strength, realizing the lightweight design of products.

5. Development Trends of Insert Molding

With the upgrading of industrial manufacturing towards high precision and intelligence, insert molding technology is constantly innovating.

5.1 Multi-Material and Multi-Insert Composite Molding

It has become the mainstream, enabling one-time molding of complex products containing multiple different types of inserts.

5.2 Wide Application of Smart Inserts

Embedding functional components such as sensors and chips into

plastic products to create smart terminal products with monitoring and transmission functions.

5.3 Digitalization and Automation

The digitalization of mold design and the automated control of the injection process continue to improve the precision and stability of insert molding, meeting the strict requirements of high-end manufacturing fields.

Conclusion

With its unique composite advantages, insert molding has become a key process for connecting different materials and integrating multiple functions, playing an irreplaceable role in modern manufacturing. In the future, with the coordinated development of material technology and mold technology, its application scenarios will be further expanded, providing more possibilities for product innovation.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China