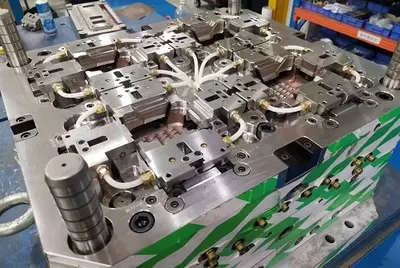

Plastic injection molding is a process where plastic raw materials are injected into the mold cavity composed of moving and fixed molds through an injection molding machine, and formed parts are obtained after cooling and solidification. During

plastic mold manufacturing and production, surface gloss defects are common problems that not only affect the appearance quality of products but also may reduce product performance and market competitiveness. This article comprehensively analyzes the core causes of mold surface gloss defects, targeted solutions, and the application of efficient optimization equipment, providing practical references for industry practitioners.

The occurrence of poor surface gloss of molds is the result of the combined effect of materials, processes, molds themselves, environment and other factors. Identifying key incentives is the premise of solving the problem.

The compatibility between material selection and process parameters directly affects melt fluidity and molding effect. When the injection temperature is too low, the plastic melt has insufficient fluidity and cannot fully fill the mold cavity, easily forming flow marks or foggy patches; when the temperature is too high, it may cause material degradation and carbonization points. In addition, too low processing pressure, slow speed, insufficient injection time or back pressure will result in poor compactness of the product and dark surface; excessive injection pressure may lead to abnormal replication of mold surface texture, causing gloss problems.

The design and processing quality of the mold are the foundation for determining surface gloss. Poor mold finish, rust on the cavity surface, or unreasonable design of the gating system (such as too small cold slug well, runner, gate size) will directly affect melt flow and molding effect. At the same time, poor mold ventilation will cause gas in the cavity to not be discharged in time, forming defects such as bubbles and burns, which indirectly damage the surface gloss; the sharp corner design of the mold is also prone to dark spots and other problems.

Traditional manual polishing is prone to uneven textures, resulting in insufficient mold surface finish, which in turn affects the consistency of product gloss. In addition, the mold surface will accumulate impurities and wear after long-term use. If a scientific maintenance mechanism is not established, gloss defects will recur, and the repair cost will gradually increase.

Dust particles in the workshop air adhering to the mold surface will form micro-pits and damage the surface flatness; poor quality of plastic raw materials or colorants, mixed with moisture or impurities, excessive proportion of recycled materials, and poor quality of lubricants will all lead to uneven melt plasticization during

custom injection molding, which is ultimately reflected in the surface gloss defects of the product.

Common gloss defects on the surface of injection molded products include dark spots, gloss differences, foggy areas and orange peel (surface wrinkling). These defects mostly occur near the gate or in the sharp corner areas far from the gate and need to be handled targeted.

Mainly appear near the gate. When molding high-viscosity, low-fluidity materials (such as PC, PMMA, ABS), the surface resin is squeezed by the flowing resin during the cooling stage.

Prone to occur during the filling and holding stages. After the injection starts, the melt flow speed is too fast, leading to dark spots in the area near the gate.

At the sharp corners of the mold or product, the excessive injection speed causes the internal fluid to squeeze the rubber material to flow, resulting in dark spots.

Too low melt temperature or mold temperature leads to insufficient melt fluidity and uneven cooling, forming surface defects.

Adopt segmented injection process, gradually increase the injection speed, reduce the front speed of the melt flow at the gate, and ensure the stable melt flow rate during the filling stage.

Increase the barrel temperature and screw back pressure to avoid insufficient melt plasticization; at the same time, raise the mold temperature to improve cooling uniformity and reduce the generation of dark spots.

Prevent cold material from entering the product, and use self-locking springs or appropriately reduce the nozzle temperature if necessary.

Unreasonable design of gate position and diameter, or sharp corners at the gate without fillet transition.

The product itself has sharp corners, and the excessive flow rate and injection speed cause the cooled surface layer to be replaced and slid by the internal fluid, forming dark spots.

Sharp angle changes in areas far from the gate affect melt flow and cooling, causing dark spots.

Optimize the design of the mold and product, adopt smooth fillet transitions in areas with sharp changes, and avoid acute angle structures.

Adjust the gate position and diameter to ensure reasonable design; adopt step-by-step injection and gradually increase the injection speed, so that the melt can increase the speed after flowing through the acute edge.

Gloss differences are particularly obvious on textured product surfaces. Even if the mold surface is uniform, irregular gloss may appear due to unstable molding parameters.

The end of the cavity far from the gate is not fully filled, and the pressure here is extremely low, resulting in the failure of accurate replication of the mold surface texture to the product surface.

Large changes in product wall thickness cause difficulties in melt flow; poor mold ventilation or excessive injection pressure will also lead to gloss differences.

Increase the melt temperature and mold temperature, increase the injection pressure and holding time to ensure full filling of the cavity and complete replication of the texture.

Optimize the mold ventilation system to avoid gas residue in the cavity; adjust the product wall thickness design to be as uniform as possible to reduce melt flow resistance.

Polish the main runner, sub-runner and gate of the mold, increase the size of the runner and cold slug well, and improve the stability of melt flow.

Mostly occurs at the end of the runner when molding thick-walled products with high-viscosity materials. During the injection process, if the melt flow speed is too low, the product surface will solidify quickly.

As the melt flow resistance increases, the front flow state becomes uneven, and the first solidified outer layer material cannot fully contact the cavity wall, forming wrinkles, which become irreversible defects after solidification and holding pressure.

Increase the melt temperature to enhance fluidity; increase the injection speed to ensure that the melt fills the cavity quickly and uniformly, avoiding premature surface solidification.

Reasonably adjust the mold temperature to improve the cooling rhythm, so that the outer layer material is fully attached to the cavity wall and reduce the generation of wrinkles.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China