In the field of

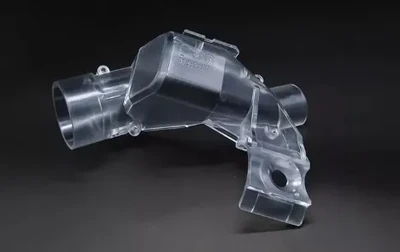

custon injection molding, transparent materials are like a magic key, opening the door to unique appearance and practical value for products. Whether it is daily necessities pursuing a crystal-clear aesthetic or industrial products with strict requirements on optical performance, choosing the right transparent injection molding material is crucial. So, what are the common transparent injection molding materials?

Mainstream transparent injection molding materials occupy the main market in the transparent injection molding field with their excellent comprehensive performance, suitable for most conventional scenarios.

PC material has a light transmittance in the range of 85%-90% with excellent optical performance. Its most notable feature is high strength and toughness, with extremely strong impact resistance, which can effectively absorb and disperse external forces to avoid material breakage.

With a wide temperature resistance range (-40℃~120℃), it is suitable for scenarios requiring high strength and safety. In the field of safety protection products, PC helmets can provide reliable protection for the head while ensuring clear vision for the wearer when subjected to external impacts; for outdoor LED lamp housings, PC injection molding can not only ensure smooth light transmission to meet lighting needs but also resist impacts from sand, gravel, etc. in complex and harsh outdoor environments, effectively protecting internal precision circuit components and extending the service life of lamps.

Commonly known as organic glass, PMMA has a light transmittance of over 92%, the best among mainstream materials, with optical performance close to optical glass.

It has high surface hardness, relatively affordable price, and excellent weather resistance, which is not easy to yellow or age when exposed to the outdoors for a long time. In the field of lighting fixtures, PMMA lamp shades can maximize light transmission and scatter evenly to avoid glare; in the manufacturing of optical lenses, relying on good optical stability and processability, it is widely used in spectacle lenses, magnifying glass lenses and other products; acrylic display stands are also often made by PMMA injection molding, which can not only clearly show the details of the exhibits but also have stable structure and not easy to deform.

PS material has a light transmittance of about 88%-90% with considerable transparency. Its biggest advantage is low cost, which makes it highly competitive in industries sensitive to cost. It also has good processing performance, and can easily fill the mold cavity during injection molding, suitable for making products of various complex shapes.

Common applications include transparent plastic tableware, whose transparent appearance can directly display food to increase appetite; small product packaging boxes often use PS materials, which can clearly show the products inside to attract consumers' attention. However, PS is relatively brittle with weak impact resistance and poor temperature resistance (continuous use temperature ≤60℃), so it should be carefully selected in scenarios that may be subject to collision.

PET material has a light transmittance of about 88%, high rigidity and good chemical resistance with stable mechanical properties. PETG improves the processability of PET, with higher toughness, lower molding difficulty, and good environmental protection and food contact safety.

Both are suitable for food contact and packaging products. Especially PETG is widely used in thin-walled packaging, disposable tableware, cosmetic packaging and other fields, which can not only meet the needs of transparency and beauty but also ensure the safety of use and processing efficiency.

COP/COC has optical performance close to PMMA, with high light transmittance, good optical uniformity and no obvious birefringence. Its temperature resistance and chemical resistance are better than PC, and it has excellent dimensional stability, with minimal product size change under different environmental conditions.

Due to its outstanding performance, COP/COC is mainly used in high-end optical products, such as optical lenses, optical films, transparent components in medical devices, etc. However, its processing difficulty is relatively large and the cost is high, which limits its application in ordinary scenarios.

These materials achieve transparency through modification technology, retaining the core advantages of the original substrate, and are suitable for personalized needs in special scenarios.

Transparent ABS achieves a light transmittance of about 70%-80% through modification process, with the core advantage of retaining the high impact resistance and rigidity of ordinary ABS, which can balance strength and transparency.

It is suitable for structural parts that need to meet both structural strength and certain transparency, such as transparent casings of some electronic devices, transparent components of automotive interiors, transparent observation windows of industrial machinery, etc., and performs well in scenarios where transparency requirements are not extreme but mechanical properties are required.

Transparent nylon has a light transmittance of about 75%-85%, with inherent excellent properties of nylon materials, such as good wear resistance, oil resistance, excellent temperature resistance and high mechanical strength.

Its applications are concentrated in high-end mechanical parts or transparent products that need to withstand harsh environments, such as transparent gears in industrial equipment, valve components, oil-resistant transparent parts in the automotive field, etc., which can maintain transparency and structural stability under complex working conditions.

AS material has a light transmittance of about 85%-90% and good gloss, making the finished products look more beautiful. It has excellent chemical corrosion resistance, can resist the erosion of various chemical substances, and has excellent dimensional stability, with minimal product size change under different environmental temperature and humidity conditions.

AS is suitable for occasions that may come into contact with chemical reagents, such as chemical reagent bottles, transparent laboratory equipment, cosmetic packaging, etc. It can also be used for transparent casings of electronic devices, toys and other products, balancing aesthetics and practicality.

Pursuit of extreme light transmittance: PMMA is preferred, with a light transmittance of over 92% and the best optical performance.

Emphasis on impact resistance and safety: PC material is the first choice, with extremely strong impact resistance and a wide temperature resistance range.

Cost-sensitive and pursuit of high cost performance: GPPS has the lowest cost and convenient processing, suitable for ordinary transparent products.

Food contact or packaging scenarios: PETG has better processability and safety, while PET is suitable for packaging products requiring rigidity.

High-end optical or precision components: COP/COC has excellent dimensional stability and optical performance to meet high-end needs.

Molding fluidity: GPPS and PETG have good molding fluidity, suitable for injection molding of complex-shaped and thin-walled products.

Processing temperature: PC requires a higher processing temperature, which has higher requirements on equipment; PS and PMMA have relatively mild processing temperatures.

Processing difficulty: COP/COC has complex processing technology and strict requirements on plastic injection mold and equipment parameter control; transparent ABS and transparent nylon need to pay attention to the matching of modification formula and processing technology to avoid affecting transparency.

Cost control: In addition to the price of the material itself, processing difficulty will also affect production costs. For ordinary scenarios, it is recommended to prioritize materials with convenient processing.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China