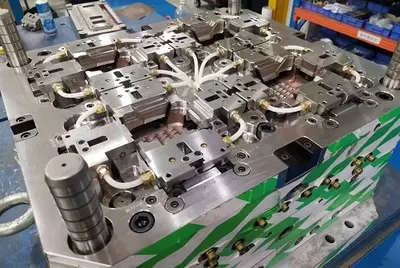

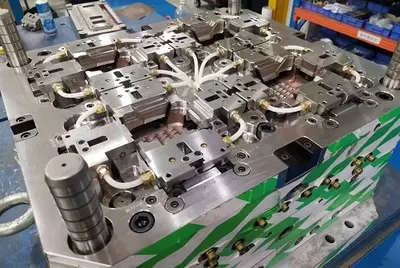

As the basic process equipment of the automobile industry, automobile molds are necessary tools for automobile parts molding. And auto parts play a decisive role in the quality of the whole vehicle, so auto molds determine the quality of auto parts. Therefore, the review of automobile molds needs to be very strict. However, there is currently no scientific and effective universal auxiliary tool to support mold review. Therefore, the mold audit at this stage is still an urgent problem for many automobile manufacturing industries.

As far as accuracy is concerned, mold review relies heavily on the experience and knowledge of engineers. The experience of each mold engineer varies, especially for new employees, which requires a process of experience accumulation. In addition, the basis information and methods adopted by different automotive mould engineers in the review process are different, so the accuracy of mold review cannot be unified.

As far as efficiency is concerned, large-scale new vehicle projects and huge mold purchases have increased the work intensity of mold engineers. Coupled with the lack of effective tools, the engineer's business processing results often lag behind the required nodes.

Therefore, the current automobile mold factory uses data strategies combined with classic predictive analysis algorithms to coordinate the data dimensions of multiple molds, and convert the volume, weight, material prices used, labor costs and other multi-dimensional data of the mold into model parameters. The meaning is extended by parameters, and the prediction models of various types of molds are constructed through machine learning algorithm fitting.

Then, in order to produce more comprehensive and accurate results, the corresponding mold cost analysis should be carried out from the perspectives of material cost, processing cost and design cost.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China