Introduction

As one of the core processes in the manufacturing industry, injection molding is widely applied in automotive, electronics, daily necessities and other fields due to its high efficiency and precision. However, waste issues in production often affect efficiency and cost control. Understanding the types and causes of waste in injection molding is crucial for enterprises to optimize processes and enhance competitiveness. This article will elaborate on the main types and causes of waste in injection molding production, and provide practical suggestions for waste reduction.

I. Main Types of Waste in Injection Molding

1. Material Waste

1.1 Manifestations

Raw material overflow, flash, defective products, or excess gate materials.

1.2 Impacts

Increases material costs and extends cleaning time.

2. Time Waste

2.1 Manifestations

Equipment downtime, excessively long mold change time, or extended debugging cycles.

2.2 Impacts

Reduces production efficiency and delays delivery schedules.

3. Energy Waste

3.1 Manifestations

Idle injection molding machines, excessive energy consumption of heating systems, or unreasonable cooling time.

3.2 Impacts

Pushes up production costs and affects environmental protection goals.

4. Defective Product Waste

4.1 Manifestations

Product quality issues such as bubbles, sink marks, and dimensional deviations.

4.2 Impacts

Leads to rework or scrapping, increasing additional costs.

5. Inventory Waste

5.1 Manifestations

Overstock of raw materials or finished products.

5.2 Impacts

Occupies capital and warehouse space, and increases management costs.

II. Main Causes of Waste

1. Improper Process Parameter Setting

Unreasonable temperature, pressure, or injection speed may lead to material waste and product defects. For example, excessively high injection pressure may cause flash, while insufficient cooling time is prone to result in sink marks.

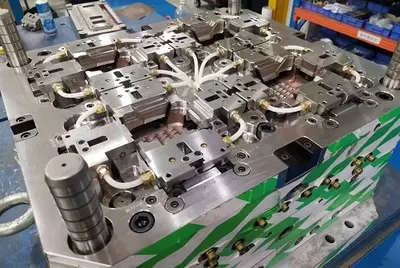

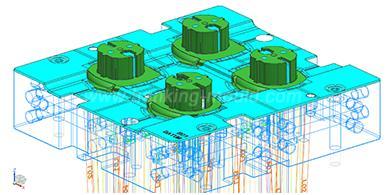

2. Mold Design Defects

Poorly designed mold runners or insufficient exhaust will cause uneven material filling, resulting in bubbles or defective products. In addition, insufficient mold maintenance may also lead to frequent shutdowns.

3. Low Equipment Efficiency

Old equipment or injection molding machines that are not maintained in a timely manner may lead to excessive energy consumption or production interruptions. Low mold change efficiency will also extend non-production time.

4. Human Operation Errors

Operators with insufficient training or experience may cause parameter setting errors, improper mold installation, or inadequate production monitoring, which in turn lead to quality problems and time waste.

5. Unreasonable Production Planning

Inaccurate demand forecasting or unscientific production scheduling may lead to inventory overstock or emergency overtime, increasing material and energy consumption.

III. Practical Suggestions for Reducing Waste

1. Optimize Process Parameters

Accurately adjust temperature, pressure, and time through experiments and simulation software (such as Moldflow) to reduce defects and material waste.

2. Improve Mold Design

Optimize the runner and exhaust system, and select high-wear-resistant materials to extend mold life and reduce maintenance frequency.

3. Upgrade Equipment and Strengthen Maintenance

Regularly maintain injection molding machines and introduce energy-saving equipment to reduce energy consumption and downtime.

4. Strengthen Personnel Training

Improve the skills of operators to ensure the stability and consistency of process implementation.

5. Implement Lean Production Management

Adopt the JIT (Just-In-Time) production concept to optimize inventory management and avoid overproduction.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China