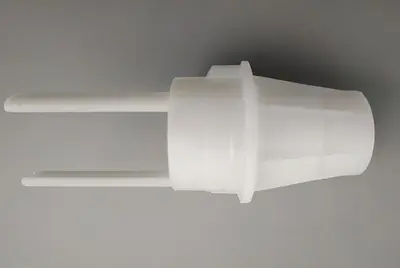

1. The part with coaxiality requirement should be formed on the core side. If it is formed in the cavity and core side, it will be difficult to ensure the coaxiality due to the inaccurate clamping.

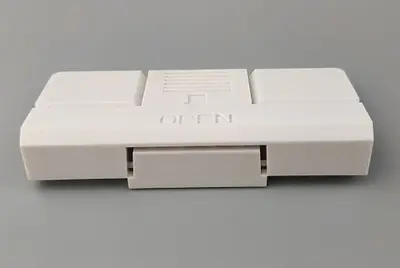

2. When selecting the parting surface, the dimension difference between the ends of the plastic part due to the draft angle should be reduced. The parting surface should be selected as much as possible without affecting the appearance of the plastic part and is able to meet the requirement of appearance. The split line and miss-match shall be submitted to the customer for confirmation;

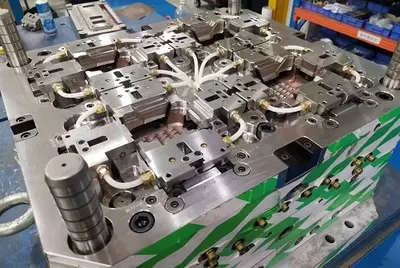

3. The distance between the plates: the determination of the parting line should ensure that the mould cavity and core opening strokes are the shortest;

4. Should avoid the core pulling mechanism as much as possible, if it is impossible to avoid the core pulling, the pulling distance should be as short as possible, and try to make the slider all in core side;

5. Since the locking force is small when the inclined slider is closed, for a large plastic part with a large projection area, the parting line of the large projection area can be placed on the main plane after the cavity and core clamped, and the smaller projected area as the lateral parting surface, otherwise the locking mechanism of the inclined slider must be very large, otherwise, the burr is occurred due to non-tight lock.

6. The determination of the parting surface does not affect the normal opening of the injection gate system, especially the two plate mold with the multi-cavity parting surface.

7. In order to help the venting of the mold, the parting surface is as close as possible to the end of the plastic material stream.

8. The overall structure of the injection mould should be simplified, the number of parting lines is minimized, and a straight parting line is used as much as possible. Should also consider whether the mold is easy to machining and process, easy to take out the finished plastic part, the parting surface should be selected as much as possible on the ridge of the plastic part.

9. Convenient installation of metal inserts.

10. Keep the product in the core side as much as possible and make sure there is enough position.

11. Sharp corners should be avoided in the parting line, as sharp corners will affect the life of the plastic injection mould. Therefore, mould designers should check very carefully. If it cannot be avoided, send a proposal to the customer whether the product can be modified.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China