Surface scratches on injection-molded products commonly affect deep-cavity items like chargers, routers, and chassis. This issue plagues glossy or textured products, often misattributed solely to insufficient draft angles. However, solving scratches requires a deeper analysis of design, machining, and process factors.

Issue: Small draft angles (typically <5° for textured surfaces) cause friction during ejection, leading to sidewall scratches.

Solution: Apply specification-based draft angles (e.g., 3–5° for fine texture, 5–8° for coarse texture). If design constraints limit draft angles, implement mold mechanisms (slides, lifters) to avoid sticking.

Fillet Design Errors:

Product fillets at parting surfaces create near-zero draft angles, increasing scratch risk. Redesign fillets to maintain draft angles ≥2°.

Gate Placement Impact:

Locate gates away from textured sides to minimize pressure-induced warpage. High gate pressure (due to long holding times) increases clamping force, risking scratches.

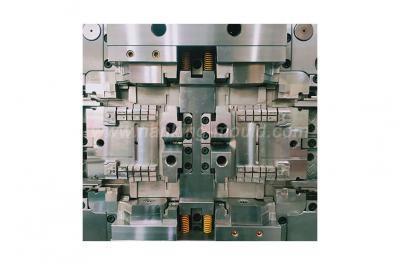

Misalignment Risks: Poor core-cavity matching during mold opening causes abrasion. Ensure precise alignment through guide pins and bolster plates.

Product Adhesion Control: Guarantee 100% core adhesion during ejection. Use core fixings (undercuts, vacuum cups) to prevent cavity sticking and warpage.

Draft Angle Measurement Gaps:

Inaccurate angle measurements during machining reduce effective draft angles. Use precision gauges (e.g., protractors, 3D scanners) for verification.

Undercuts from Polishing:

Polishing near mold bases often creates undercuts, while parting surfaces may lose draft angles. Implement controlled polishing techniques (e.g., directional buffing) to maintain angles.

Excessive Pressures: High injection/holding pressures (e.g., >100 MPa) induce stress, causing warpage and sidewall contact. Reduce pressures step-by-step to balance filling and stress.

Temperature Effects: Overheated materials (e.g., >280°C for ABS) soften surfaces, increasing scratch susceptibility. Optimize barrel temperatures within material specs.

Inadequate Cooling: Insufficient cooling (e.g., <30% of cycle time) leads to soft parts that scratch easily. Extend cooling time until surface temperature <50°C.

Machine Aging: Worn injection machines with misaligned plates vibrate during opening, abrading parts. Regularly check plate parallelism and replace worn components.

Specify minimum draft angles based on texture roughness; avoid fillets at parting surfaces.

Position gates to minimize stress on textured areas; use fan gates for uniform flow.

Validate draft angles with precision tools during machining; implement anti-undercut polishing protocols.

Reinforce mold rigidity to prevent parting surface bulging (e.g., using hardened steel).

Tune injection parameters (pressure, speed, temperature) to reduce stress; monitor clamping force (<80% of machine capacity).

Maintain machine maintenance schedules to ensure plate alignment and minimal vibration.

Surface scratches in injection molding demand a systematic approach across design, manufacturing, and processing to ensure defect-free production of high-quality parts.

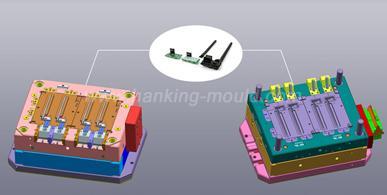

We specialize in custom plastic injection mold production service in China and injection molding processes for 20 years, contact yoyo@hanking-mould.com for your plastic products projects.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China