1. The shape and dimensional accuracy of the finished precision mould, the flow direction of the resin, the transmission of the injection pressure, and the solidification of the filled resin are the conditions that a precision mould designer should know about the product requirements. This is also the source of precision mold design. Therefore, the requirements of the product must be well-informed.

2. Characteristics of precision mould forming products. It is necessary to have a very systematic list of the characteristics of the molded product, mainly in terms of materials and the shape of the molded product. There will be a basis for some details of the following precision mold design.

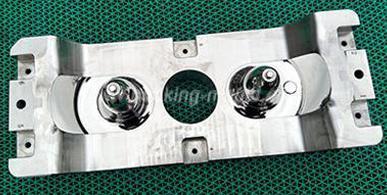

3. The structure of the precision mould is different from that of the ordinary mold. There may be several possible structural design schemes for ordinary plastic molds, but some structures of precision molds may have certain influences, so the structural schemes of some precision molds may be very demanding. It is mainly to consider the influence of precision mold action on the product.

4. Rigidity and strength of precision moulds. In our experience, the rigidity of precision moulds is important. It is often seen that the mold base and inner mold material of some precision molds are very thin. Maybe the mold can be produced, but some product problems are closely related to the strength of the mold, and sometimes it is difficult to find. If the strength of the precision mold is to keep the mold from breaking, we think this is a very unreasonable idea, and it is also a manifestation of lack of experience in precision mold design.

5. The glue inlet and horizontal glue channel of the precision mould are important factors to control the product. Precision molds have certain requirements for the glue feeding method of the product. Making the glue point better will have unimaginable effects on the product.

6. Precision mould temperature control circuit. Precision molds should be controlled at a uniform temperature. It is necessary to set the temperature difference required in the resin flow direction, and countermeasures are required for thickness changes. When the molded product is released from the mold, the surface temperature of the precision mold in the product department should be uniform. This requires the precision mold cooling system to be reasonable.

7. The precision requirements of precision moulds are very high, and the processing methods used to process precision molds are very important. Divide the mold cavity of the product according to the shape of the molded product. Therefore, the processing method should be considered when designing.

8. The structure of the precision mould should be reasonable to facilitate the addition of other programs. For example, a position may be unsatisfactory. If it is really unsatisfactory after the mold trial, a back-up plan should be adopted.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China