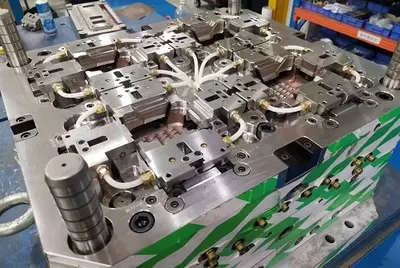

The principle of injection molding is to add granular or powdered raw materials into the hopper of an injection machine. The raw materials are heated and melted into a flowing state. Under the push of the screw or piston of the injection machine, they enter the mold cavity through the nozzle and the pouring system of the mold, and harden and solidify in the mold cavity.

Now, we're diving into the fascinating world of injection molding and the wide array of plastic products that are brought to life through this innovative manufacturing process. From household items to electronic gadgets and automotive components, injection molding plays a crucial role in creating the everyday items we rely on. So, sit back, relax, and let's explore the magic of molding together!

Household Items

Ever wondered where those plastic cups and containers in your kitchen came from? Well, chances are they were born through the wonders of injection molding. This manufacturing method allows for precise and efficient production of a variety of household items, from storage containers to cutlery and utensils. So next time you reach for a plastic cup, remember the intricate process that brought it to your shelves.

When you're getting ready in the morning, take a moment to appreciate the plastic products that make your personal grooming routine a breeze. Shampoo and conditioner bottles, toothbrushes, razors, and even makeup containers all undergo the injection molding process to ensure quality and consistency. These everyday essentials are just a small glimpse into the vast world of plastic products created through injection molding.

Your smartphone, laptop, and TV remote all have one thing in common – they rely on injection molded plastic components to function. Phone cases, chargers, computer mouse parts, and keyboard components are just a few examples of the many electronic devices that benefit from the precision and durability of injection molding. The next time you're scrolling through your favorite app, remember the intricate process that brings your devices to life.

Hit the road and you'll find that your trusty vehicle is full of plastic components created through injection molding. From dashboard panels and interior trim to exterior body parts and engine components, injection molding plays a vital role in the automotive industry. These durable and versatile plastic products not only enhance the aesthetics of your car but also contribute to its overall performance and longevity.

As we reach the end of our journey through the world of plastic products made by injection molding, it's important to reflect on the impact of these everyday items. While plastic products have undoubtedly enhanced our lives in countless ways, it's crucial to consider their environmental footprint and explore recycling options to minimize waste.

So, the next time you use a plastic product, take a moment to appreciate the magic of injection molding and the intricate process that brings these items to life. Who knew that a simple plastic cup or electronic gadget could hold such a fascinating story behind its creation? Here's to the creativity and innovation of injection molding and the endless possibilities it brings to our daily lives!

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China