As a mold supplier, HANKING MOULD ENGINEERING LTD. can provide the following services:

1. Design of mold drawings.

2. Design of product drawings.

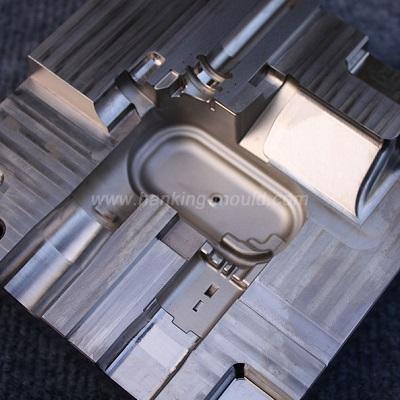

3. Mold injection molding analysis: mold flow analysis.

4. Save mold design and mold two-dimensional drawing for five years.

5. The part number will be marked on the two-dimensional drawing of the mold for customers to quickly inquire and re-customize the damaged part.

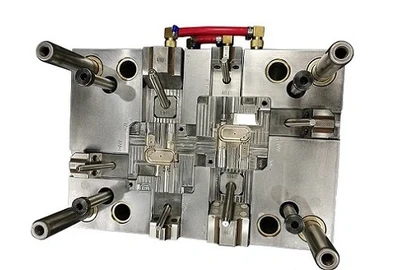

6. The same or similar parts on the mold will be uniformly designed in size for interchangeability.

7. As a mold supplier, we will meet customer needs in time.

HANKING MOULD ENGINEERING LTD. provides 24-hour online service. After receiving your inquiry, we will serve you as soon as possible. We will analyze your products and provide the corresponding quotation plan.

We will analyze the mold flow of each mold and provide the analysis report to the customer. When the processing of each component is completed, we will conduct quality inspection to ensure the eligibility of each component.

Before the mold is shipped to your factory, if you need, we can appoint engineers to do on-site debugging, or you can arrange personnel to do remote precise training and learning - mold debugging and maintenance, etc. And we will be equipped with wearing parts for customers to replace.

HANKING MOULD ENGINEERING LTD. has an experienced engineering service team, we support global service! And we support door-to-door installation and debugging to ensure the stable operation of the mold.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.