When molten plastics meet in multiple forms in a mold cavity due to insertion holes, regions of discontinuous flow rate, and regions of interrupted mold fill material flow, linear fusion joints are created due to incomplete fusion. In addition, the sprue injection molding will also produce a fusion seam, and the strength of the fusion seam is very poor. Let's share the main reasons below.

1. Processing:

1) The injection pressure and speed are too low, and the barrel temperature and mold temperature are too low, which will cause the molten material entering the mold to cool prematurely, so that a fusion seam will appear.

2) If the injection pressure and speed are too high, injection and fusion joints will appear.

3) Speed and back pressure should be increased to reduce viscosity and increase plastic density.

4) The plastic should be dry, and the recycled material should be used as little as possible. If there is too much release agent or the quality is not good, it will also lead to fusion seams.

5) The clamping force is minimized, which can facilitate exhaust.

2. Mould:

1) When there are too many gates in the same cavity, they should be narrowed or set symmetrically, or set as close as possible to the fusion seam.

2) If the exhaust at the fusion joint is not smooth, it is necessary to set up an exhaust system.

3) If the runner is too large and the size of the gating system is not suitable, try to avoid the melt flowing around the insert hole or use as little insert as possible.

4) It is not acceptable if the wall thickness changes too much or is too thin. The wall thickness of injection molded products should be uniform.

5) If necessary, a fusion well should be opened at the fusion seam to separate the fusion seam from the fabricated part.

3. Plastic:

1) Appropriate amount of lubricant or stabilizer is added to plastics with poor fluidity or poor heat sensitivity.

2) It is unacceptable that the plastic contains a lot of impurities, and it is necessary to replace the plastic with good quality.

Rigid plastic parts such as PS form dense corrugations, sometimes called corrugations, on the surface near the gate. The reason is that when the melt viscosity is too high and the mold is filled in the form of stagnant flow, the material at the front end will condense and shrink as soon as it contacts the surface of the cavity, and then the melt expands, and the shrinking cold material continues to move forward, making the material flow in the cavity. Surface shock lines are formed during forward motion.

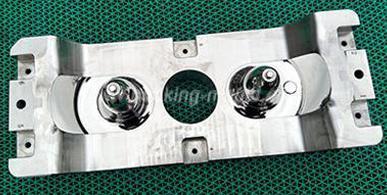

HanKing Mold designs and manufactures plastic injection molds in China, providing large factories for our global customers, and also provides injection molding production services. If necessary, welcome to consult.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China