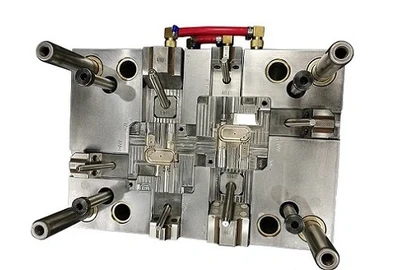

Plastic injection tooling is specially applied in plastic product production, which can meet the requirements of various structures and design dimensions of plastic products. When producing batches of some products with complex structures, plastic injection tooling can significantly improve production efficiency. Its structure is as follows:

The parts that give the shape, structure, and size of the molding material are usually composed of cores (punch), concave mold cavities, threaded cores, inserts, etc.

It is a channel that leads the molten plastic from the nozzle of the injection machine to the closed mold cavity, usually composed of the main flow channel, runner, a gate, and a cold material well.

In order to ensure that the moving die and the cover die can be accurately aligned when they are closed, the guiding fitting is provided for guiding and positioning. It is composed of a guide post and a guide sleeve, some of which are also equipped with guiding fitting on the ejector plate to ensure the smooth and reliable demolding mechanism movement.

There are many structural forms of the device that realizes the demolding of plastic parts and the gating system; the most commonly used ejector mechanisms include ejector rod, ejector tube, ejector plate, and pneumatic ejector, which are generally composed of ejector rod, reset rod, slingshot, ejector rod fixing plate, top plate (top ring), and top plate guide post/guide sleeve.

For plastic parts with side holes or undercuts, before they are ejected and demolded, they must have side core-pulling or separation from the slider (lateral parting) before they can be demolded smoothly.

Mold temperature adjustment systems (such as cooling water, hot water, hot oil, and electric heating systems) adjust the mold temperature to meet temperature requirements.

An exhaust groove is usually set at the mold's parting surface to facilitate the exhaust of gas. Besides, the gaps between the pushrods of many molds or other movable parts (such as sliders) can also play a role in the exhaust.

There are some parts set to meet the mold structure requirements (such as fixed plate, moveable/static template, support head, support plate, and connecting screw).

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China