Why Two Shot Injection Molding is Super Useful

Two Shot Injection Molding is a really cool way to make things out of plastic. It's like being able to use two colors or types of plastic at the same time to create awesome toys or useful items!

Introduction to Two Shot Injection Molding

We'll start by explaining what Two Shot Injection Molding is and why it's a cool way to make things out of plastic. Imagine being able to use two colors or types of plastic at the same time to create awesome toys or useful items!

What is Plastic Injection Molding?

Here, we'll talk about how people make stuff out of plastic by melting it and squishing it into molds to get the shape they want, which is what plastic injection molding is all about.

The Melting and Molding Process

You'll learn how plastic starts as tiny pellets, gets all melty, and then is pushed into cool shapes, a bit like using a playdough mold!

The Coolness of Two Shot Injection Molding

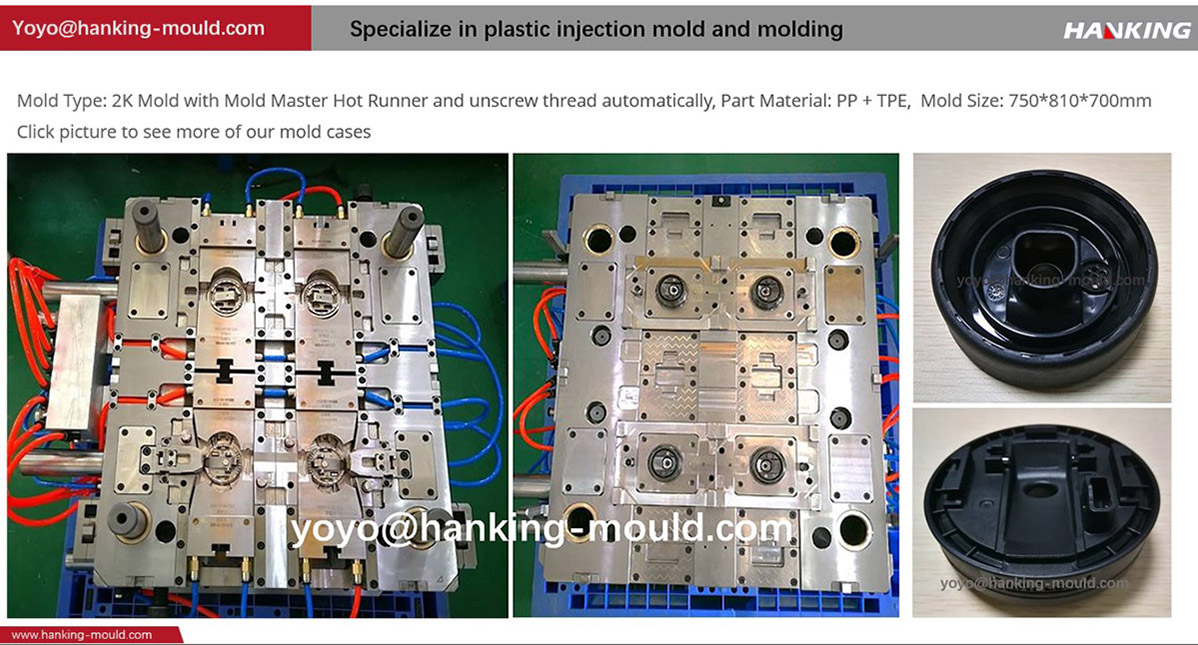

This part explains how Two Shot Injection Molding is like doing the regular molding process twice in a row but with different plastics, so you can have two colors or types without gluing them together!

Why Use Two Plastics Instead of One?

We'll explore why someone might want to use two types of plastic in one piece, like for making parts that need to be soft in some places and hard in others.

Two Shot Injection Molding is super cool because it allows us to create objects using not just one, but two different types of plastics at the same time. Imagine having a toy that is both red and blue without having to stick them together! It's like magic but with plastic.

One of the main reasons why people use Two Shot Injection Molding is to combine different properties of plastics. For example, you can have a toy that is soft and squishy in some parts, perfect for squeezing, and hard and sturdy in others, great for holding its shape. This technique gives us the best of both worlds in one single piece!

Exploring Multi-Shot and Overmolding Techniques

Now we'll dive into other cool tricks, like multi-shot injection molding and overmolding, which are exciting techniques used in plastic injection molding.

Multi-Shot Molding Wonders

Multi-shot molding is like using a magic wand to create intricate and special items out of plastic. Instead of just two types of plastic, you can use even more shots to make something truly unique and amazing. It's like painting with different colors, but with plastic!

Overmolding Magic

Imagine wrapping one plastic around another, like wrapping a cozy blanket around a toy. That's what overmolding plastic is all about! It's used to add a soft, grippy layer to things like toothbrushes or game controller buttons, making them more comfortable to use. Overmolding is like giving your favorite things a special hug.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China