1. Process analysis of plastic products.

Before the die design, the designer should fully analyze whether plastic products conform to the principle of injection molding. It is necessary to consult with the designer carefully and reach a consensus. It includes the necessary discussion of the geometric shape, dimensional accuracy and appearance requirements of the products, and avoids the unnecessary complications in injection mold building as far as possible.

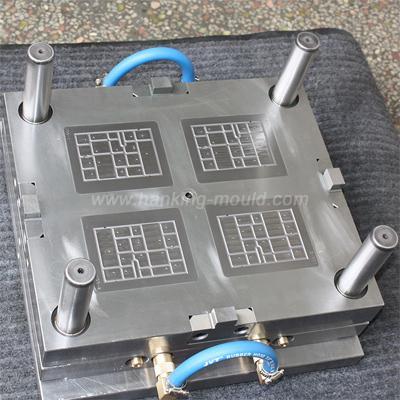

2. Design of die structure.

A set of high-quality die not only needs good processing equipment and skilled injection mold builder but also a very important factor is to have good die design, especially for complex dies, the quality of die design accounts for more than 80% of the quality of the die. Excellent die design is: on the premise of meeting the customer's requirements, the processing cost is low, the processing difficulty is small, and the processing time is short.

3. Determining die materials and selecting standard parts.

In the selection of die materials, besides the accuracy and quality of products, the correct selection should be made according to the actual ability of processing and heat treatment in the dying factory. In addition, in order to shorten the manufacturing cycle, the existing standard parts should be used as much as possible.

4. Part processing and die assembly.

In addition to giving the best structure and reasonable tolerance coordination in the design of the precision of the die, parts processing and die assembly is very important. Therefore, the selection of processing accuracy and methods plays an absolute leading role in die manufacturing.

Therefore, in order to reduce injection mold building error, first of all, the processing accuracy should be improved. With the use of CNC machine tools, this problem has been well controlled. In addition, in order to prevent the errors caused by the wear and deformation of the die, quenching treatment should be applied to the key parts such as the cavity and core of the die when the processing precision is high and the output of the product is high. In order to save material and facilitate processing and heat treatment, the mosaic structure should be adopted in die design.

In order to solve the errors caused by uneven shrinkage and inconsistency between pre-contraction and actual contraction, the product tolerance of 1/3 is generally selected as injection mold building tolerance in injection mold building. The purpose is to leave greater room for adjustment in the later forming process, so as to solve the errors caused by the forming process.

5, model test.

A set of molds starts from design to assembly, only 70% to 80% of the whole manufacturing process is completed. For the errors caused by the inconsistency between pre-contraction and actual contraction, the smoothness of demoulding and the cooling effect, especially the influence of gate size, position, and shape on the accuracy and appearance of products, it must be checked by test mold. Therefore, die testing is an indispensable step to check whether the die is qualified or not and to select the best forming process.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China