Bubble Defects in Plastic Injection Parts: Causes and Solutions

In injection molding production, bubble defects are a persistent challenge even for experienced manufacturers. These bubbles not only compromise the molding quality of plastic injection parts but also cause production delays and increased costs. Bubbles typically appear in the thick walls or final weld lines of products, and targeted solutions must be adopted based on their root causes. This article summarizes the key causes of bubbles and provides practical remedies, with a focus on optimizing processes and custom plastic molds performance.

1. Core Causes of Bubble Defects

Bubble formation in plastic injection parts is closely related to raw material quality, process parameters, and custom plastic molds design. The main causes are as follows:

1.1 Raw Material and Temperature-Related Factors

Excessive Temperature: Prolonged exposure to high temperatures causes plastic degradation, releasing gas that forms bubbles. Overheating can also lead to black decomposition lines; mild cases can be resolved by cooling, while severe barrel decomposition requires disassembly and cleaning.

Moisture and Volatiles in Raw Materials: Unprocessed or improperly stored raw materials contain excess moisture or volatile substances, which vaporize during molding and form bubbles.

Poor Raw Material Quality: Impure raw materials or incompatible additives may react at high temperatures, generating gas.

1.2 Process Parameter Issues

Improper Injection Pressure/Speed: Excessively high injection pressure (often caused by overfeeding) or speed traps air in the melt. In high-pressure environments, trapped air is scorched by friction and encapsulated in the product, forming internal cavities—especially in solid plastic injection parts.

Insufficient Cooling Time: Incomplete cooling of thick-walled parts leads to internal shrinkage, creating voids that appear as bubbles. External cold pressing molds can be used to supplement cooling if needed.

1.3 Custom Plastic Molds Design and Maintenance Problems

Poor Ventilation: Accumulated debris on the mold cavity or inadequate venting channels prevent air from escaping, leading to bubble formation—particularly in thick-walled sections.

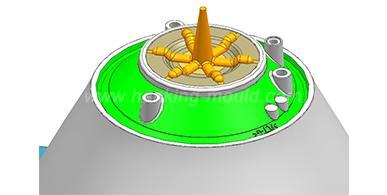

Undersized Gates or Imbalanced Gating: Mismatched gate sizes and product weights in multi-cavity custom plastic molds cause uneven filling, with thick parts more prone to bubbles. Undersized gates increase flow resistance, trapping gas.

Lack of Regular Maintenance: Neglected mold cleaning leads to residue buildup, blocking vents and disrupting normal filling.

2. Targeted Solutions for Common Bubble Scenarios

Different bubble manifestations require specific remedies, combining process adjustments and custom plastic molds optimization.

2.1 Surface Swelling and Bubbles in Thick-Walled Parts

2.2 Internal Cavities with Blackening in Solid Parts

2.3 Bubbles in Thick Sections of Products

3. Comprehensive Prevention and Control Measures

To fundamentally reduce bubble defects in plastic injection parts, a systematic approach covering materials, processes, and custom plastic molds is required:

3.1 Raw Material Management

3.2 Process Parameter Optimization

Fine-tune temperature, injection pressure, and speed based on material properties and part structure—avoid overheating, overpressure, or excessive speed.

Extend cooling time appropriately for thick-walled parts to ensure complete solidification.

3.3 Custom Plastic Molds Optimization and Maintenance

Design adequate venting channels (recommended depth: 0.02–0.05mm) at flow ends, weld lines, and thick sections.

Balance gate sizes in multi-cavity molds and avoid undersized gates.

Establish a regular mold maintenance system: clean residues, inspect vents, and polish cavities to ensure smooth filling.

4. Conclusion

Bubble defects in plastic injection parts can be effectively controlled through a combination of raw material quality control, process parameter optimization, and

custom plastic molds improvement. By accurately identifying the cause of bubbles (whether process-related or mold-related) and implementing targeted solutions, manufacturers can significantly reduce defects, improve product quality, and enhance production efficiency. Continuous monitoring and refinement of the entire production process are key to maintaining stability and meeting the high standards of plastic injection parts manufacturing.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China