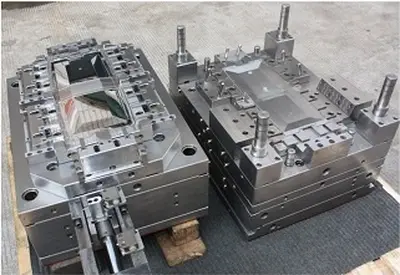

During the process of operating and developing a small car mold factory, it is necessary to gradually grow from small to large. We know that any enterprise experiences the pain of a small factory during the business process before gradually moving towards standardization. Below, let's take a look at how small auto mold processing factories can quickly improve their competitiveness and accurately position themselves in the market in the face of fierce market competition.

To survive, it is necessary to constantly improve the level of technology and production efficiency, and products can only be well developed if they are recognized by the market. Therefore, to position a company well, it is also necessary to analyze the position of the mould making company itself and confirm the future development direction after segmentation.

Any enterprise during the process of business development needs to establish its own brand. Small auto mold factories should also focus on producing a branded car mold during the business process, because this can expand market sales through increasing brand awareness, occupy a larger share in the market in the future, and be more advantageous during the process of business development.

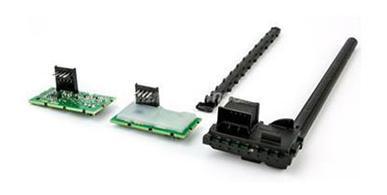

During the process of making automotive molds, there are certain technical procedures and skills that require professional technical personnel to collaborate to ensure the quality of the molds. Customized products based on customer needs are widely used in the market and can basically ensure that the factory can improve its competitiveness and occupy a place in the market.

Small automotive moulding company need to constantly enhance their own technical research and development capabilities in order to develop new products, because the rate of product updates in the market is very fast. If they only produce traditional molds, it will be difficult to operate well in the market. Therefore, during the business process, they should constantly improve their research and development capabilities and develop new products according to customer needs.

Set sales targets for new products every year. Although there is a certain cost during the research and development and debugging stages, as long as the products can quickly enter the market, the profit margin will be very large. Small enterprises should have such development directions and goals during the development process, and can naturally operate the enterprise better.

The precision requirements of molds in the market are very high now. To make small auto mold factories more recognized by more customers in the market, the precision degree of the whole mold process should be improved, and the precision value of the product should be high, which can also meet the needs of more people in this market.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China