There are three ways of heat transfer: radiation, convection and conduction. The heat generated when the plastic enters the automobile mold is absorbed by the mold through conduction, and about 5% of the heat is dissipated into the air through radiation and convection.

1. In the process of injection mold processing for automobile mold manufacturers, temperature change is the most important factor. It has a great impact on the quality of finished products and indirectly affects production efficiency.

2. The mold temperature control mode of automobile mold manufacturers is the liquid cooling mold flowing in the cooling pipe, because water is very cheap, so water is used as the main coolant for cooling the mold, which can shorten the rapid cooling time by guiding the mold.

Generally, it is more efficient than cold molding because it allows for faster production cycles. However, this is not necessarily true, as some materials are too cold, which has the opposite effect.

3. Beryllium copper inserts are usually used in automobile molds to improve the cooling effect of injection molds. The mold can quickly transfer heat to the cooling water flowing through the beryllium copper material with good thermal conductivity, and take it away to achieve cooling effect.

There are also high-melting plastics that need to be heated and injected into automotive molds. For example, resistance wire heating rods are embedded in the mold blank to heat the mold. Liquids, water, and oils for plastic mold cooling; water, ice water, and water plus antifreeze are commonly used. Instead, hot water is used to heat the mold when the mold temperature needs to be increased.

A large temperature difference also indicates that the design of the cooling water circuit is not ideal. The pressure loss of the cooling water channel in the mold can also be obtained by measuring the pressure difference between the water channel and the inlet and outlet, and can judge whether the water channel design is reasonable.

4. The heat balance control of the injection mold of the automobile mold manufacturer is one of the keys to determine the quality of the injection molded product. How to choose and control should be closely combined with the structure, performance, function and requirements of the product to ensure quality and reduce costs.

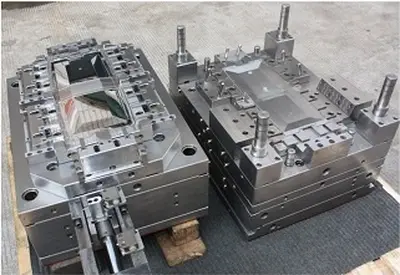

HanKing Mold designs and manufactures plastic injection molds in China, provides large factories for our global customers, and also provides customers with injection molding production services, including secondary processing and assembly, our global customers are from the United States, Germany and other parts of the world, Switzerland, France, Italy, Austria, Israel, etc.

The company's business philosophy is "customer first, quality first", and it is a trustworthy injection mold manufacturing company. Welcome to consult.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China