This is classified according to the purpose of the finished terminal product, involving electronic plastic parts and electrical plastic accessories.

In modern society, more and more products use electronic components. Medical equipment, home appliances, and automotive products, etc. all use electrical parts.

The first is good part design, second is good mold design, precision equipment and skilled technician is also very critical.

The structure of the product should be reasonable and can be completely released from the mold, so our customers will discuss with us before making the mold. We welcome customers to send an inquiry, and it is very happy to work together to create high-quality products. Normally, we will give suggestions related to parting line, gate location & type, ejection location, surface finishing, angle draft analyze, wall thickness analyze and send part design optimization proposal to the customer.

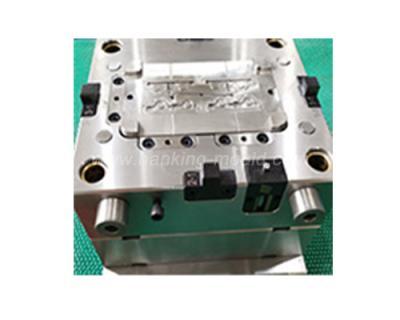

We use the milling machines, CNC machines, grinding machines, EDM, wire cutting machines to make injection mould, and make injection mold trials with Haitian injection machines.

In generally there are internal plastic parts and external plastic parts, dimension is very important for internal functional parts, most of the time, as long as the steel size of the mold is within tolerance, the dimension of the part that is injection molded will not NG.

And the external parts are visible, and must have a good appearance. In addition to the corresponding processing of the mold surface, the injection molding machine setting is also very important, usually, need to try a large number of parameter combinations when making mold trial.

Call us on:

Call us on:  Email Us:

Email Us:  1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China

1st Floor, Block1, No.3 Beiting Road, Houting Community, ShaJing Street, Bao'An District, Shenzhen City, Guangdong Province, China