At present, more than 90% of plastic products in our daily life are injection molded. The market prospect, capacity, and application are large and wide. The following are the basic review of plastic injection moulds' classifications.

Hanking Plastic Injection Moulds includes automotive mold, electronic mould, home appliance mould, medical mould, insert molding, industrial mould, prototype mold, 2K mould, multi-cavity mould and precision mould, and they can be applied in various lines such as industry, automotive, environment, electronic, and consumers.

The demand for plastic parts in the automotive industry is increasing day by day. No matter how extreme the operating temperatures are and how harsh the chemicals, Hanking can provide a variety of engineering-grade thermoplastics.

Plastic electronic enclosures are used throughout our daily lives, such as remote control housing, plug plastic housing, electrical machine plastic cover, router housing, office appliances case, adapter charger housing mould, terminal block, mobile phone housing, terminal devices, computers products.

Household appliances plastic parts basically include interior plastic parts mold and the exterior plastic housing and case, which we use on a daily basis.

As the population is increasing, the medical segment is one of the fastest-growing markets, including disposable medical products as well as medical equipment internal parts.

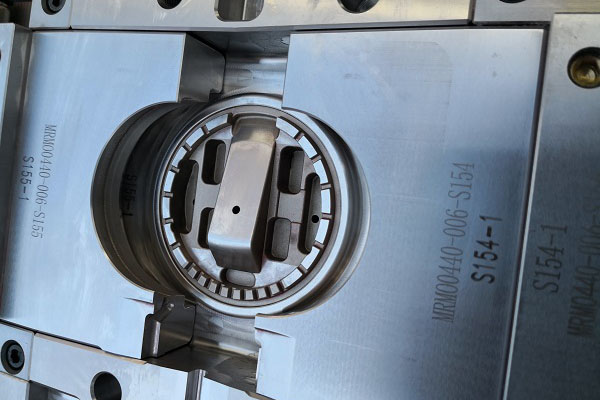

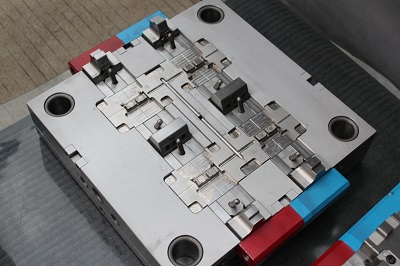

Insert molding refers to a molding process in which we prepare an empty cavity on two or more mold-specific metals, and metal material inserts into a mould and then injecting the plastic resin, and the molten material is bonded to the insert, cooled and solidified.

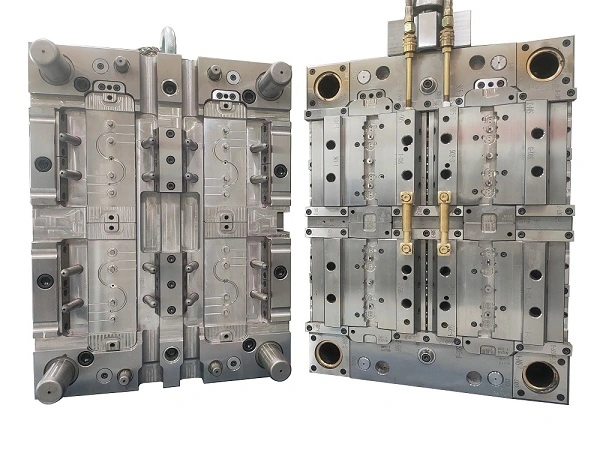

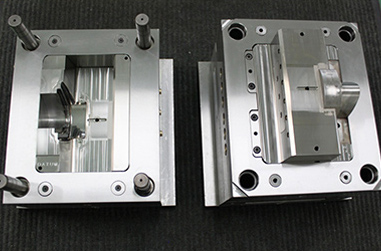

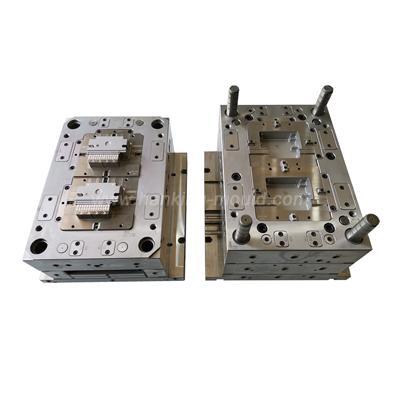

The industrial mold is an unbeatable benefit amplifier. Machining products with molds greatly improve production efficiency, and also saves raw materials, reduces energy consumption and costs, and maintains high product consistency. It includes side plate mould, pinpoint plate mould, three plate mould, reverse gating mould and stack mould.

Prototype mould is made for pre-testing of large production, such as product structure, part function analysis and produces small lot parts for other process verification. It can reduce errors in design and risks in the development, and reduce the time for training users, which improves the system's practicality, correctness and user satisfaction.

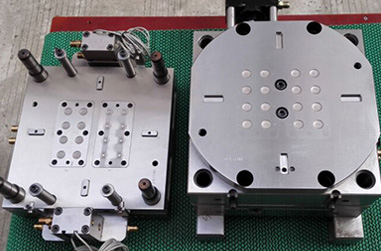

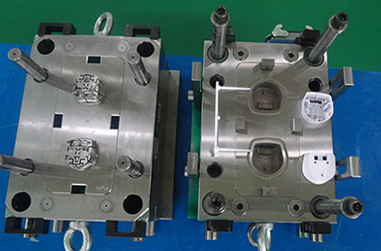

The multi-cavity mould can produce multiple workpieces in one injection cycle for increased efficiency. It comprises a multi-cavity of the same plastic part and a multi-cavity of different plastic parts.

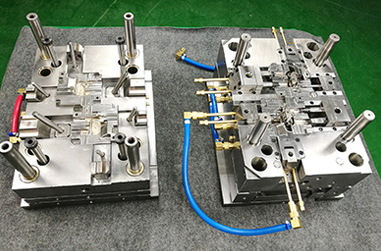

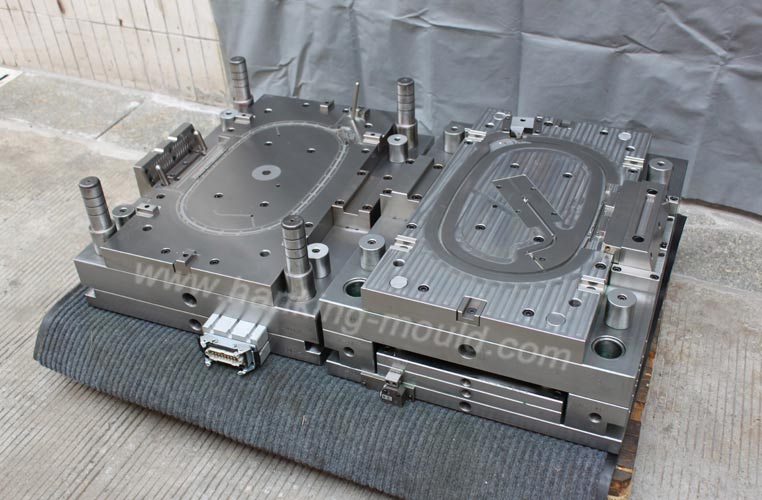

In HanKing Mould, we have a complete set of high-precision measurement equipment, they are all of the strict size requirements, product consistency, complex structure and durability. Our precision mould can offer full dimension FAI measurement reports. We have high-quality injection plastic molding molds for sale, contact us now.

The plastic injection mold industry is an important part of the national high-tech industry and a valuable technical resource. We optimize the structural design of the mold system and make it more intelligent, improve the forming process and mold standardization of the part, improve the precision and quality of the mold manufacturing, and reduce the amount of grinding and polishing of the surface of the part. Our plastic injection mold can be the development trend of mold production technology in the next decades.

Call us on:

Call us on:  Email Us:

Email Us:  No 4, BeiQu Road, ChenCun village, Humen town, Dongguan City, Guangdong Province, China.

No 4, BeiQu Road, ChenCun village, Humen town, Dongguan City, Guangdong Province, China.