In today's fierce market competition, the replacement of new models is increasingly frequent, and the car development cycle has been calculated on a monthly basis. In the entire automobile development cycle, the most important part is automotive moulds, especially the automobile body panel mold and the internal and external trim injection mold. Whether you are a car manufacturer or a supplier of auto parts, it is especially important to find an automotive mold maker with excellent quality and good service. Because the quality of interior and exterior parts of a car is related to the overall quality of a car and the brand image of the car manufacturer. HANKING MOULD ENGINEERING LTD has many years of rich experience in manufacturing various plastic automobile molds. Through strict quality control, it can provide automobile suppliers with better quality automobile interior and exterior parts. And it can be delivered within one month at the earliest.

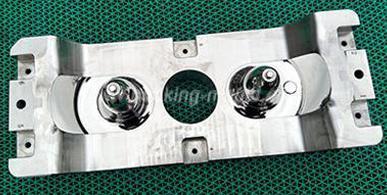

Various automotive moulds require high mold processing equipment to control accuracy, and have high polishing requirements for processing equipment. Due to the complex structure of automotive moulds, we invested a lot of money to purchase high-precision mold processing equipment. The application of these devices will make the surface of automotive interior and exterior trim look brighter, thereby saving more mold polishing time.

In addition, we have a strong automotive mold design team, and the designers have at least 5 years of automotive interior and exterior trim mold design experience. According to customer requirements, we will provide you with reasonable automotive mold design. The designed mold has a good cooling system, ventilation system and optimal injection system. Our car mold design has more freedom of choice and more room for modification.

If you want to know more information about automotive moulds, you can contact us immediately, HANKING MOULD ENGINEERING LTD. will serve you wholeheartedly.

Call us on:

Call us on:  Email Us:

Email Us:  No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.

No.23, XingYi Road, Wusha Community, Chang'an Town, Dongguan City, Guangdong Province, China.